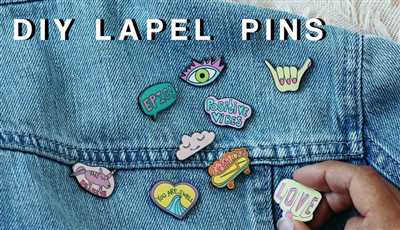

Have you ever wondered how those beautifully crafted pins that people wear on their jackets or bags are created? If you’re reading this, then chances are you’ve thought about designing your own custom lapel pin. Well, you’re in luck! In this guide, we’ll take you through the step-by-step process of creating a pin from start to finish.

First, let’s explore the options available for making lapel pins. There are several different methods, but one of the most popular is the die-struck process. This involves creating a mold of the desired pin shape and then striking a metal, such as brass or zinc, into the mold. The result is a raised and recessed design that gives the pin a three-dimensional look.

After the pins are struck, they go through a plating process to give them their final finish. The most common plating options are gold, silver, and nickel, but there are many other finishes available, such as antique and black nickel. The plating not only enhances the appearance of the pin but also helps to ensure its durability.

Once the pins are plated, the next step is to add the enamel. This is where the pin really comes to life. Enamel is a type of colored glass that is applied to the raised and recessed areas of the pin. The enamel is then fired at a high temperature to create a smooth, glossy surface. This layer of enamel not only adds color but also provides protection for the design, making the pin suitable for everyday wear.

After all the plating and enameling is done, the pins are carefully inspected to ensure they meet the highest quality standards. Once the pins pass inspection, they are packaged and shipped to their new owners. Whether you’re a designer looking to create a unique promotional item or just someone who wants to add a personal touch to their outfit, lapel pins are a great way to showcase your style and make a statement.

So, now that you know how lapel pins are created, go ahead and explore your options! Design your own custom pin, or browse through the many pre-made designs available. The possibilities are endless, and there’s a pin out there for everyone. And if you need any help along the way, don’t hesitate to reach out to a pin manufacturer or designer who can guide you through the process. Happy pin-making!

- Guide to Creating Your First Enamel Pin

- What are Enamel Pins?

- How Are Enamel Pins Made?

- Why Create Your Own Enamel Pin?

- Are enamel pins popular

- What Happens After The Pins Are Shipped To You

- How to make enamel pins

- Explore the ideal options for purchasing your custom pins

- Video:

- How to Make Enamel Pins! // designing, ordering, & tricks for good results // #gs-jj #custompins.ca

Guide to Creating Your First Enamel Pin

What are Enamel Pins?

Enamel pins are small, decorative accessories that are typically worn on clothing or attached to bags. They are made by adding colored enamels to a metal base, creating a durable and vibrant design. Enamel pins have become incredibly popular in recent years, and people all around the world are embracing them as a form of self-expression.

How Are Enamel Pins Made?

Creating enamel pins involves several steps, each contributing to the final product. Here is a step-by-step guide to help you understand the process:

| Step | Description |

|---|---|

| 1 | Design Your Pin: Start by working with a designer to create the ideal pin design. You can explore various options, such as shape, colors, and size, to ensure that your pin reflects your vision. |

| 2 | Create a Mold: Once the design is finalized, a mold is created. This mold will be used to replicate your design onto the metal base of the pin. |

| 3 | Add Enamel: The metal base is then filled with colored enamels, creating a vibrant and eye-catching design. Different colors are added layer by layer, allowing for intricate and detailed designs. |

| 4 | Bake the Pin: After adding the enamel, the pin is heated to high temperatures, allowing the enamels to bond securely to the metal. |

| 5 | Apply Plating: Once the baking process is complete, the pin is plated with a metal coating, such as gold, silver, or zinc, to give it a finished look and added durability. |

| 6 | Quality Check: Each pin goes through a strict quality check to ensure that it meets the desired standards. This includes inspecting the design, colors, and overall finish. |

| 7 | Packaging and Shipping: After passing the quality check, the pins are carefully packaged and shipped to their intended destination, ready to be worn or shared with others. |

Why Create Your Own Enamel Pin?

There are several reasons why creating your own enamel pin can be a great idea:

- Custom Design: You have the freedom to create a pin that perfectly matches your style and personal taste.

- Thoughtful Gifts: Enamel pins make great gifts for friends, family, or colleagues. They are unique and can be customized to suit the recipient’s interests.

- Popularity: Enamel pins have gained immense popularity in recent years, making them a trendy accessory to wear or collect. Creating your own pin allows you to join in on the trend.

- Pinmatics: The pin community is thriving, and by creating your own pin, you become part of a community of pin enthusiasts that can help and support each other.

Now that you have a guide to creating your first enamel pin, you’re ready to explore the options available and start bringing your pin design to life. Happy pin-making!

Are enamel pins popular

Enamel pins have become increasingly popular in recent years, gaining a substantial following around the world. These small items have made a big splash in the fashion and accessories industry, captivating people with their unique designs and eye-catching colors.

So, how are enamel pins made?

Enamel pins are created through a process known as “enamel pin making”. The first step in creating an enamel pin is for the designer to come up with a great pin design. Once the design is finalized, it is then used to create a mold for the pin. Pinmatics, a company that specializes in enamel pin manufacturing, offers a free pin design guide to help you explore your options.

After the mold is created, the next step is to form the pin shape. This can be done using a variety of materials such as zinc alloy or copper. The mold is filled with the chosen metal and then baked to ensure durability. Once the pin shape is set, the next step is to add the enamel colors.

Enamel pins get their vibrant colors from enamel powder, which is essentially colored glass. The enamel powder is mixed with water to form a paste-like consistency and is then applied to the pin, filling in the recessed areas of the design. After the enamel is applied, the pin is fired in a kiln to melt the enamel and create a smooth, glass-like surface.

There is a difference between hard enamel pins and soft enamel pins. Hard enamel pins are polished to be smooth and have a flat, reflective surface, while soft enamel pins have raised metal borders and a textured surface. Both types have their own unique appeal and it’s up to you to decide which style fits your ideal design.

Once the pin is created and the enamel is set, it is then plated with a metal finish such as gold, silver, or black nickel. This plating helps to enhance the overall appearance of the pin and protect it from tarnishing.

After the plating process, the enamel pins are inspected and packaged for shipping. Many designers and businesses offer custom enamel pins, allowing individuals to create their own unique designs. These pins can be worn on jackets, bags, hats, or displayed as a collector’s item.

So, why are enamel pins so popular?

Enamel pins give people an opportunity to express their personal style and interests. There are pins available for virtually any topic or hobby, making it easy to find a design that resonates with you. Whether you’re a fan of pop culture, nature, or vintage aesthetics, there is an enamel pin out there for you.

Enamel pins also make great gifts. They are affordable, customizable, and can be a unique way to show someone you care. Whether it’s a birthday gift, a thank you gift, or just a little token of appreciation, an enamel pin can make a thoughtful and memorable present.

In conclusion, enamel pins are undeniably popular due to their versatility, unique designs, and customizability. Whether you’re a collector, a fashion enthusiast, or someone looking to add a touch of personal style, enamel pins offer a world of options and possibilities. So, if you haven’t already, why not give enamel pins a try?

What Happens After The Pins Are Shipped To You

After you’ve received your lapel pins, the pin-making process continues to ensure that you’re getting the best quality product. The pin-making process involves a lot of thought, precision, and attention to detail to give you a pin that you can proudly wear.

At Pinmatics, we start by creating a mold based on your design. This mold is made from zinc, which is a popular material for creating pins due to its durability and versatility. The mold gives the pin its shape and design, ensuring that it’s just as you wanted.

Once the mold is created, the next step is plating. This is where a layer of metal, such as gold, silver, or copper, is applied to the pin. This plating not only adds a visually appealing touch to the pin but also acts as a protective layer, making it more durable and long-lasting.

After plating, the pin goes through an enamel filling process. Enamel is a colored liquid that is applied to the recessed areas of the pin’s design. This process helps to create a more eye-catching and vibrant pin, giving it a great finishing touch.

Once the pin is plated and filled with enamel, it’s time for quality control. Each pin is carefully inspected to ensure that there are no defects or imperfections. If any issues are found, the pin goes through a reworking process to fix the problem.

After quality control, the pins are packaged and shipped to you. We take great care in packaging the pins to ensure that they arrive in perfect condition. Whether you’re purchasing pins for personal use or as promotional items, we know how important it is for the pins to look great when they reach you.

So, what happens after the pins are shipped to you? Now it’s your turn to wear and enjoy them. Lapel pins are a popular accessory for people of all ages and backgrounds, and there are various options available to help you display your pins in style.

If you’re a designer or just someone who loves creating custom pins, we offer free guides and resources to help you make the most out of your pin-making experience. Our pin designer tool, for example, allows you to explore different design options and see how they would look on a pin. We want to ensure that you’re empowered to create the ideal pin for yourself or your organization.

So, after reading about how lapel pins are made, you now have an understanding of the amount of time, effort, and attention to detail that goes into creating a lapel pin. Whether you’re wearing them for personal reasons or using them for promotional purposes, these pins are more than just items – they’re a way to make a difference and showcase what you care about.

| Materials: | Zinc, Enamel |

| Process: | Mold Creation, Plating, Enamel Filling, Quality Control |

| Aftercare: | Wear and Enjoy, Display with Style |

| Additional Options: | Free Pin-Making Guide, Pin Designer Tool |

How to make enamel pins

Enamel pins have become a popular item to add to any fashion ensemble or accessory. If you’ve ever wondered how these unique pins are made, read on to explore the step-by-step guide.

First and foremost, you’ll need a design. Whether you’re a seasoned designer or just someone who thought of a great idea, your first step is to create a design that will be the basis for your enamel pin. You can explore various options such as shape, color, and any additional details you want to add.

Once you have your design, it’s time to bring it to life. Custom enamel pins are typically made from zinc alloy, a durable metal that can be easily molded. This material ensures that your pin will be sturdy and can withstand daily wear and tear.

To make the pin, a mold is created based on your design. This mold will then be used to cast the zinc alloy and create the pin’s shape. The pins are then plated in a layer of metal, such as gold or silver, to give them a polished and high-quality look.

After the plating process, the pins are filled with enamel, which is a special type of colored paint. This enamel is carefully added to each section of the design to ensure that the colors stay vibrant and do not mix together. The pins are then heated to help the enamel set in place.

Once your pins are complete, they’re ready to be shipped out to you. There are many companies, such as Pinmatics, that specialize in creating custom pins and offer free shipping options. You can also choose from a wide range of other options, such as different metal plating or additional features like glitter or glow-in-the-dark enamel.

Now that you know how enamel pins are made, you can appreciate the thought and effort that goes into creating such unique items. Whether you’re wearing them to express yourself or as a way to support a cause, these pins are a great way to show off your style and make a difference.

Explore the ideal options for purchasing your custom pins

When it comes to custom lapel pins, there are several options available to give you the perfect pin for your needs. Whether you’re creating pins for your business, organization, or event, it’s important to consider your design, materials, and plating options to ensure you get the ideal pins for your intended purpose.

The first step in creating your custom pins is to have a design in mind. Whether you already have a clear vision or need some help bringing your ideas to life, many pin manufacturers offer design services to help you create a pin that perfectly represents your brand or message.

Once you have your design, the process of making the pins begins. The design is first transferred onto a mold, which will shape the pin. This mold is then used to create the pin through a process called pinmatics.

With the pin shape decided, you can now choose the material for your pin. The most popular options include brass, zinc alloy, and iron. Each material has its own characteristics, so consider factors such as weight and durability when making your choice.

After the pin is created, it goes through a plating process to give it its final appearance. Common plating options include gold, silver, nickel, and black nickel. Different plating choices can give your pin a different look, so think about the effect you want to achieve with your design.

Enamel pins are a popular choice for many people, as they allow for vibrant colors and intricate details. After the plating process, the colors are added using a high-quality enamel that is carefully applied to the pins. This creates a smooth and shiny surface that really makes the design pop.

Once all the steps are completed, your custom pins are ready to be shipped to you. Pin manufacturers usually offer free shipping for your convenience, so you can have your pins delivered right to your doorstep.

Now that you know how custom pins are created, let’s discuss the various options for purchasing them. There are many online pin manufacturers and distributors that offer a wide range of pin styles and options. Whether you’re looking for a simple design or a complex, multi-colored pin, there’s sure to be a manufacturer that can provide exactly what you’re looking for.

Some pin manufacturers also offer additional items such as backing cards or presentation boxes to enhance the overall appeal of your pins. These extra touches can give your pins a professional look and make them more suitable for gifting or selling.

When purchasing custom pins, it’s important to choose a reputable manufacturer. Look for reviews and testimonials to ensure you’re working with a reliable company that will deliver on their promises. A great way to ensure you’re getting high-quality pins is to request samples before placing a bulk order.

With so many options available, it’s easy to get overwhelmed. But by taking the time to research and thoughtfully consider your needs and preferences, you can find the ideal custom pins to suit your requirements. Whether you’re looking to promote your business, reward your employees, or commemorate a special event, custom pins are a great choice to make a lasting impression.