If you’re looking to start printing your own vinyl labels, you’ve come to the right place. Printing vinyl labels can be a fun and creative way to personalize your belongings or even start your own business. In this article, we will guide you through the process of printing vinyl labels, from choosing the right materials to printing and cutting.

When it comes to printing vinyl labels, you have a few options. One option is to use a home printer with printable vinyl sheets. These sheets usually come in packs and are available in different sizes, including standard letter size (8.5 x 11 inches). The advantage of using printable vinyl sheets is that you can print your labels at home without the need for a special machine.

Another option is to use a vinyl cutting machine, like the ones offered by Uninet. These machines are designed specifically for cutting vinyl and can produce professional-looking labels. However, they usually require additional software and setting up the machine can be a bit more complex.

Once you have your materials ready, it’s time to start printing your vinyl labels. Make sure your artwork is prepared and saved in the right format, such as PDF or PNG. If you’re using a home printer, choose the glossy or waterproof option if available. If you’re using a vinyl cutting machine, make sure to choose the right type of vinyl and laminate for your project.

Materials You Need to Make Waterproof Vinyl Stickers at Home

When it comes to printing vinyl labels at home, there are a few essential materials you will need to ensure your stickers are waterproof and durable. Here is a list of the key supplies:

| 1. | Vinyl Sheets or Rolls |

| 2. | A Printer |

| 3. | Laminate Sheets |

| 4. | Cutting Machine |

First and foremost, you will need high-quality vinyl sheets or rolls that are specifically designed for printing. Make sure to select a size that is suitable for your printer.

Next, a reliable printer is crucial in ensuring your vinyl stickers come out with professional-looking results. Inkjet printers are the most popular option, but some people prefer laser printers for their longevity and durability.

Included with your vinyl sheets should be laminate sheets, which will be used to protect the printed artwork. The laminate will serve as a waterproof barrier and add a glossy finish to your stickers.

A cutting machine, like the Silhouette Cameo or Cricut Maker, is essential for precision cutting of your printed vinyl. These machines allow you to easily create intricate designs without the need for any manual cutting.

Other materials you will need include white paper for scanning or creating your artwork, software for editing and printing your designs, and toner for laser printers, if applicable.

Before starting the printing process, make sure to set your printer to the appropriate settings for vinyl printing. This may include adjusting the paper type and print quality. Consult your printer’s manual for specific instructions.

Overall, with the right supplies and equipment, you can create your own waterproof vinyl stickers at home. Whether you are a DIY enthusiast or running a sticker-making business, these materials will ensure professional-looking results that will last for weeks or even months.

1 Answer 1

If you are looking to print vinyl labels, there are a few options you can choose from when it comes to the type of printer you use. While most printers are designed for printing on regular paper, there are some that are specifically made for printing on vinyl and other materials.

One option is to use a dedicated vinyl printer. These machines are usually more expensive than regular printers, but they are designed to handle the unique properties of vinyl. They typically have a wider range of settings and can print on thicker materials without causing any damage to the machine.

If you already have a printer at home and don’t want to invest in a new one, another option is to use a laser printer. Laser printers use toner instead of ink, which makes them a good choice for printing on vinyl. Just make sure to adjust the printer settings to the appropriate type of material you’re using.

When it comes to the vinyl itself, you can choose between printable vinyl or regular vinyl. Printable vinyl allows you to print your own designs directly onto the vinyl, while regular vinyl requires you to cut out your designs using a cutting machine, such as a Cricut or a Silhouette.

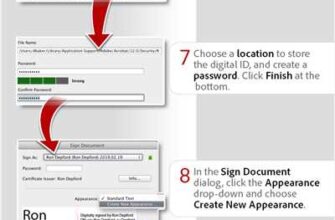

If you are using printable vinyl, you will need to make sure that your artwork is properly prepared. There are different software programs, such as Adobe Photoshop or CorelDRAW, that you can use to create and edit your designs. Once your design is ready, you can print it onto the printable vinyl using your chosen printer.

If you are using regular vinyl, you can start by cutting out your designs using a cutting machine. Make sure to choose the appropriate blade and settings for the type of vinyl you’re using. Once your designs are cut out, you can apply them to your desired surface.

Regardless of the type of vinyl you choose, you may also want to consider adding a glossy laminate over your prints. This will provide extra protection and make your labels more durable and waterproof.

In conclusion, when it comes to printing vinyl labels, you have a few options to choose from. Whether you decide to invest in a dedicated vinyl printer or use your existing laser printer, make sure to choose the right materials and settings to achieve the desired result. And always remember to properly prepare your artwork before printing. Happy printing!

DIY Vinyl Decals Supplies

If you’re looking to make your own vinyl decals at home, there are a few supplies you’ll need to get started. Here is a list of the essential materials and equipment:

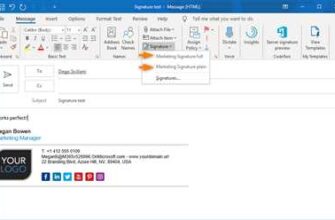

1. Printer: You will need a printer that is capable of printing on vinyl. Laser printers are usually the best option for this, as they produce waterproof and durable prints. The Uninet iColor line of printers is a popular choice for DIY vinyl decals.

2. Vinyl: Choose a high-quality vinyl material that is suitable for decals. Look for vinyl that is printable and compatible with your printer. Waterproof and glossy vinyl is usually the best choice for long-lasting decals.

3. Cutting machine: If you want to create custom shapes for your decals, you will need a cutting machine. The Silhouette Cameo and Cricut machines are popular choices among DIYers. These machines can scan and cut your artwork with precision.

4. Lamination: To protect your printed decals from water, UV rays, and scratches, you should always laminate them. Choose a laminate that is compatible with your printer and the vinyl you are using. Laminating your decals will make them more durable and long-lasting.

5. Software: You will need design software to create or modify your artwork for the decals. Adobe Illustrator and CorelDRAW are popular choices, but there are many other options available. Make sure the software you choose can handle vector graphics and is compatible with your printer.

6. Other Supplies: In addition to the above, you will also need some basic supplies such as scissors, a weeding tool to remove excess vinyl, transfer tape to apply the decals, and a measuring tool to ensure accurate sizing.

With these supplies in hand, you’ll be ready to start making your own DIY vinyl decals. Just make sure to follow the instructions included with your printer, cutting machine, and other equipment, and you’ll be making professional-looking decals in no time!

Choose Your Vinyl Printer

When it comes to printing vinyl labels, choosing the right printer is crucial. There are several factors to consider, such as the size of your artwork, the type of vinyl you’re using, and whether you want to print in color or just in black and white. Here are some important things to keep in mind when selecting a vinyl printer:

1. Laser printers: Laser printers are always a good option for printing vinyl labels. They use toner, which is waterproof and won’t smudge or run when exposed to water. Laser printers also produce high-quality prints with crisp lines and vibrant colors.

2. Inkjet printers: Inkjet printers can also be used to print vinyl labels, but it’s important to make sure you’re using printable vinyl and not regular paper. The inkjet printer will apply ink to the vinyl, but without proper adhesion, the prints may not be waterproof or long-lasting. It’s recommended to use an inkjet printer if you plan on laminating your labels after printing.

3. DIY machines: If you’re looking for a more cost-effective option, you can consider DIY vinyl printing machines. These machines typically come with their own software for designing and printing labels. However, the quality may not be as high as professional printers, and you may need to do some experimenting to find the right settings for your vinyl and artwork.

4. Professional printers: If you’re willing to invest in a high-quality vinyl printer, there are many professional options available. Companies like Uninet and Canon offer printers specifically designed for printing on vinyl. These printers usually come with advanced features and produce professional-grade prints.

5. Choosing the right supplies: Once you have your printer, you’ll also need to choose the right vinyl and other materials for your labels. Make sure to select vinyl that is compatible with your printer and choose a size that fits your needs. You may also want to consider glossy or matte vinyl, depending on the look you want to achieve.

6. Scanning and editing software: If you’re going to be scanning and editing artwork for your vinyl labels, make sure you have the necessary software. Programs like Adobe Photoshop or CorelDRAW can help you edit and resize your designs to fit the dimensions of your labels.

By considering these factors and doing your research, you can find the perfect vinyl printer for your needs. Whether you’re printing labels for your home studio or for a professional business, a reliable printer will ensure that your vinyl stickers come out looking their best.

Sources

When it comes to printing vinyl labels, there are several sources you can consider to get the materials and equipment you need. Here are some options:

1. DIY Approach: If you’re looking to print vinyl labels at home, there are a few items you will need. First, you’ll need a printer that is compatible with printable vinyl. One popular option is the Canon Pixma series, which offers high-quality prints on glossy vinyl. You’ll also need printable vinyl sheets, which can be purchased online or at your local office supply store. Additionally, you may want to invest in a laminating machine to protect your prints and make them more durable.

2. Professional Printing Studios: If you don’t want to handle the printing process yourself and want a more professional-looking result, you can always take your artwork to a printing studio. These studios usually offer a wide range of services, including vinyl label printing. They have advanced machines and cutting-edge software to ensure high-quality and precise prints. Some studios also offer additional services like scanning your artwork or cutting the labels to size.

3. Online Suppliers: Another option is to find online suppliers that specialize in vinyl labels and sticker printing. Websites like Uninet provide a variety of options for custom labels and decals. They offer different sizes, materials, and finishes, such as glossy or waterproof, giving you more flexibility in choosing the right option for your needs. These suppliers usually have easy-to-use online tools that allow you to upload your artwork and customize your labels without ever leaving your home.

Regardless of the option you choose, it’s important to make sure that the materials and equipment you’re using are suitable for printing on vinyl. Always check the specifications and user manuals before starting your printing process to ensure the best results.