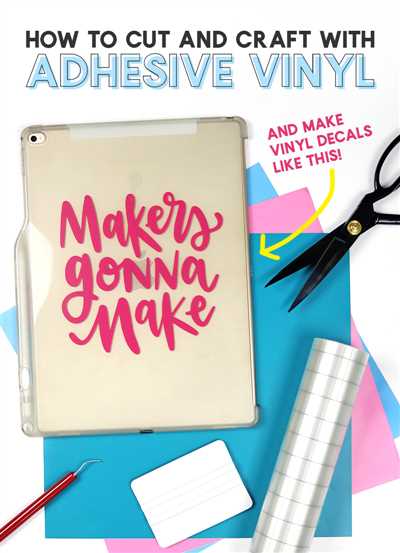

If you have a passion for designing and creating, vinyl decals are a perfect way to express your creativity. Whether you want to make personalized stickers for your laptop, phone, or car, or you’re starting a business selling custom decals, this guide is for you. Vinyl decals are easy to make and offer a wide range of possibilities for customization.

First, let’s talk about what vinyl decals are. Vinyl decals are designs or artwork made from a thin, self-laminating vinyl film. They come in various colors and sizes and can be printed on using a vinyl cutter or a printing device. Vinyl decals are often used for window stickers, vehicle graphics, signs, labels, and more. They are durable, weather-resistant, and can last for years without losing their color or appearance.

There are two main methods for creating vinyl decals: the direct-to-surface method and the transfer tape method. The direct-to-surface method involves cutting the design directly on the vinyl sheet, while the transfer tape method requires an additional step of transferring the design from the backing sheet to the desired surface.

To start making vinyl decals, you’ll need a few tools and materials. These include a vinyl cutter or a cutting machine like Cricut, vinyl sheets in your desired colors, transfer tape, a squeegee or a roller, and a pair of scissors. Additionally, if you want to add a glossy or laminating finish to your decals, you can use a self-laminating vinyl or a clear glossy film. This will give your decals a superior quality and protection.

Now, let’s go through the step-by-step process of making vinyl decals using the direct-to-surface method:

- Design your artwork on a computer or scan it if you have a physical copy.

- If needed, resize the design to fit the desired size of your decal.

- Load the vinyl sheet into the vinyl cutter and make sure it’s aligned properly.

- Select the appropriate settings for cutting the vinyl, such as speed and pressure.

- Send the design to the vinyl cutter and wait for it to complete the cutting process.

- After cutting, remove the excess vinyl around the design using a weeding tool or a small pair of scissors.

- Apply transfer tape to the front of the design, making sure to align it perfectly.

- Use a squeegee or a roller to firmly press the transfer tape onto the vinyl, ensuring that the design adheres well to the tape.

- Peel off the backing sheet from the vinyl, leaving the design on the transfer tape.

- Place the transfer tape with the design onto the desired surface and press it firmly to make sure it sticks properly.

- Gently peel off the transfer tape, leaving the design on the surface.

- Use a squeegee or a roller to smooth out any bubbles or wrinkles.

- Allow the decal to dry completely before touching or peeling off any excess tape.

And there you have it – your very own vinyl decal! Whether you’re creating decals for personal use or for profit, this guide will help you achieve professional-quality results. The possibilities are endless when it comes to vinyl decals, so let your creativity run wild and start designing today!

Our complete Self-Adhesive Vinyl guide

If you’re passionate about designing and making your own custom vinyl decals, our complete self-adhesive vinyl guide is here to help. With the right tools and a little know-how, you can create professional-looking decals for a variety of projects.

First, let’s talk about the materials you’ll need. You’ll want to have self-adhesive vinyl sheets, a cutting machine (such as a Cricut), a laptop or phone for designing, and a squeegee or roller for applying the decals. Additionally, having masking tape, a water spray bottle, and a sharp utility knife on hand will be helpful.

To start, open your design software on your laptop or phone. Whether you’re using a premade design or creating your own, make sure it’s the right size and format for printing. Consider the color scheme and appearance you want for your decal, as well as any additional effects like glossy or transparent finishes.

Once your design is ready, load the self-adhesive vinyl into your cutting machine. Make sure the vinyl is properly aligned and the blade is set to the correct depth. Then, let the machine do its work and cut out your design.

After cutting, carefully remove the excess vinyl from the backing sheet. This process is known as weeding. Use a sharp utility knife or weeding tool to remove any small, intricate pieces. Take your time and be careful not to damage the design.

Now it’s time to apply the decal to your desired surface. If you’re working on a large area, it may be helpful to have a friend assist you. Clean the surface thoroughly and make sure it’s dry before applying the decal.

If your decal is small enough, you can peel off the backing sheet and apply it directly. If it’s a larger decal, you may want to use a masking tape method. Place a strip of masking tape along one edge of the decal, then fold the decal in half with the adhesive side out. This will create a hinge that allows you to position the decal on your surface.

Spray the surface with a little water to make it slightly wet. This will make it easier to reposition the decal if needed. Carefully position the decal on the surface, using the hinge as a guide. Once in position, use a squeegee or roller to firmly apply the decal, starting from the center and working your way out.

If your decal has any bubbles or wrinkles, carefully lift the edge with a utility knife and reapply. Continue to smooth out the decal until it adheres well to the surface.

If you want to add an extra layer of protection to your decal, consider laminating it. You can use a self-laminating film or take it to a professional laminating service. This will extend the lifespan of your decal and make it more resistant to water and UV rays.

With our complete self-adhesive vinyl guide, you’ll be able to create high-quality vinyl decals for all your projects. Whether you’re making decals for your car, laptop, or any other surface, following these steps will ensure a professional and long-lasting result. Happy crafting!

Materials

When it comes to designing and making vinyl decals, there are a few essential materials that you’ll need. These materials are important for ensuring the quality and appearance of your decals.

First and foremost, you’ll need vinyl sheets. Vinyl is the main material used for making decals, and it comes in various colors and sizes. You’ll want to choose a vinyl that is self-adhesive and has a glossy finish for a professional and attractive look.

Another important material is transfer tape. This is a transparent film that you’ll use to transfer your vinyl design from the backing paper to the desired surface. It helps to keep your design intact and prevents any damage during the transfer process.

A cutting device is also necessary for making precise cuts in your vinyl. You can use a cutting machine or even a simple pair of scissors depending on the complexity of your design. It’s important to have a sharp cutting tool to ensure clean edges and smooth lines.

In addition to the basic materials, there are a few additional tools that can make the process of making vinyl decals easier. These include a squeegee, which is used to smooth out any air bubbles or wrinkles in the vinyl, and pinch-rollers, which help to feed the vinyl smoothly through the cutting device.

If you’re planning to make decals for your car or any other outdoor projects, a laminate film is recommended for extra protection against UV rays and weathering. This will help to ensure that your decals last for years without fading or peeling.

Lastly, you may also need a printer if you’re designing printable decals or if you want to scan and print out existing artwork. Make sure to use high-quality printer ink and printable vinyl sheets for the best results.

In conclusion, the materials you choose for making vinyl decals are essential for the quality and longevity of your creations. From vinyl sheets to transfer tape, cutting devices, and additional tools, having the right materials is key to making professional-looking decals. So, make sure to invest in superior materials and support your passion for vinyl decal making!

What Types of Decals Can I Make

When it comes to vinyl decals, the possibilities are virtually endless. Whether you’re looking to add a personal touch to your laptop or create custom stickers for your business, there are a variety of decal types you can make to suit your needs.

Here are some of the most popular types of decals:

| Clear Vinyl Decals | These decals are printed on clear vinyl material, which allows for a seamless and professional appearance on any surface. Clear vinyl decals are perfect for adding subtle designs or logos to windows, glass, or transparent surfaces. |

| White Vinyl Decals | White vinyl decals offer superior color vibrancy and are ideal for designs that require a solid white background. They are versatile and can be applied to a variety of surfaces, making them great for both indoor and outdoor use. |

| Self-Adhesive Vinyl Decals | These decals are designed to stick onto surfaces without the need for any additional adhesive. They are easy to apply and can be removed without leaving any residue behind. Self-adhesive vinyl decals are a popular choice for projects that require a quick and convenient application method. |

| Waterproof Vinyl Decals | If you’re looking to create decals that can withstand exposure to water, such as on water bottles or car windows, waterproof vinyl decals are the way to go. These decals are made with materials that are resistant to water damage, ensuring that your designs stay intact even after being exposed to moisture. |

| Self-Laminating Vinyl Decals | For added protection and durability, self-laminating vinyl decals are a great option. These decals have a clear layer that can be applied over the printed design, providing a glossy and transparent finish. The laminating layer not only enhances the appearance of the decal but also protects it from scratches and fading over time. |

| Printable Vinyl Decals | If you have a passion for designing your own decals, printable vinyl decals are a must-have. With a compatible inkjet printer, you can easily print your designs onto printable vinyl sheets and then cut them using a vinyl cutter. This opens up a world of possibilities for customizing your decals with unique logos, graphics, or even photos. |

No matter what type of decal you choose to make, it’s important to use high-quality vinyl materials and employ proper cutting and application techniques. With the right tools and support, you can create stunning decals that will last for years to come.

Step 3: Use Masking Tape Dry Method

When it comes to applying vinyl decals, the dry method using masking tape is one of the most convenient and time-saving techniques.

Here is a step-by-step guide on how to use the masking tape dry method for applying vinyl decals:

- First, make sure that your surface is clean and free from any dust or debris. It’s important to have a smooth and even surface for the vinyl decal to stick properly.

- Next, prepare your vinyl decal by removing the backing. Peel off the protective backing from the vinyl decal, exposing the adhesive side.

- Position the vinyl decal on the desired area of your surface. Use masking tape to temporarily secure the decal in place. This will allow you to make adjustments if needed before fully adhering it.

- Once the decal is positioned correctly, use a squeegee or any flat-edged tool to press the vinyl decal onto the surface. Start from the center and move towards the edges to avoid any air bubbles.

- Remove the masking tape slowly and carefully, ensuring that the vinyl decal remains adhered to the surface.

- If there are any air bubbles or wrinkles, use a pin or needle to prick the vinyl and smooth it out.

The masking tape dry method is great for small to medium-sized vinyl decals and designs. It provides a clear and glossy appearance without the need for water or any other liquid.

Using this method, you can achieve a professional-looking vinyl decal application on various surfaces, such as windows, laptops, and even cars.

For larger vinyl decals or designs, it may be more convenient to use a Cricut or other cutting machine to create and cut out the design. This allows for precise and intricate designs without the hassle of manually cutting.

Remember to always follow the manufacturer’s instructions for the specific vinyl decal you are using. Some decals may require additional steps, such as laminating the design or using transfer sheets for easier application.

Overall, the masking tape dry method is a quick and easy way to apply vinyl decals to achieve a professional and long-lasting result. It saves you time and ensures a superior appearance for your vinyl decal projects.

Designing for a Passion or Profit

Designing vinyl decals can be an exciting way to express your creativity and turn your passion into a profitable business. Whether you’re creating designs for personal use or selling them to others, there are a few key steps to keep in mind to ensure the best results.

First, decide on the purpose of your design. Are you creating it for yourself, or do you plan to sell it? This will help determine the size, colors, and overall appearance of your design.

If you’re starting from scratch and need some inspiration, take a look at what other people are doing in the vinyl decal industry. You can search online for designs, visit local craft stores, or attend trade shows to get ideas for your own artwork.

Next, gather the necessary materials and tools. You’ll need self-adhesive vinyl sheets, a cutting device (such as a Cricut machine), transfer tape, a squeegee, and a clear self-laminating film for added protection. Depending on the size and complexity of your design, you may also need pinch-rollers to help feed the vinyl through the cutting machine.

Once you have your materials ready, it’s time to start designing your decal. Use design software or a document editor to create your artwork or upload a photo. Ensure that the design is the correct size and resolution for your intended surface.

When cutting your design, make sure to choose the appropriate settings on your cutting device. Test on a small vinyl area before cutting the complete design to ensure accuracy.

After cutting, carefully peel off the excess vinyl from around your design. Use transfer tape to lift your design off the backing and apply it to the desired surface. Use a squeegee to remove any air bubbles and ensure a smooth application.

For outdoor decals, consider using waterproof and UV-resistant vinyl. This will provide long-lasting protection against fading and other environmental factors. Additionally, self-laminating film is a great option for added durability and a glossy finish.

Whether you’re creating decals for personal use or selling them, quality is important. Ensure that your designs are clean, crisp, and have vibrant colors. Check for any errors or imperfections before finalizing the design.

Finally, when it comes to selling your decals, make sure to take high-quality photos that accurately represent your designs. Create a professional-looking product listing with detailed descriptions, size options, and pricing. Consider offering bundle deals or custom designs to attract more customers.

Whether you’re designing vinyl decals for passion or profit, following these steps will help you create eye-catching and high-quality products. With the right tools and a little creativity, you can turn your love for design into a successful business or a fulfilling hobby.

| Tips: |

|---|

| – Gather all the necessary materials before starting |

| – Take inspiration from other designs in the industry |

| – Use high-quality vinyl and consider adding a clear self-laminating film for additional protection |

| – Test your design on a small vinyl area before cutting the complete design |

| – Take high-quality photos and create professional product listings when selling your decals |