If you’re a design enthusiast looking to add a variety of customized and high-quality accessories to your collection, creating your own enamel pins may be the perfect project for you. Enamel pins have become increasingly popular in recent years, allowing people to showcase their creativity and personal style. Although the process may seem daunting at first, with a little planning and the right tools, you can create your own unique enamel pins that bring your designs to life.

One of the most important steps in creating enamel pins is deciding on the design. Whether you want to hand-draw your design or use digital tools to bring it to life, it’s essential to ensure that your design meets the requirements of the pin manufacturers. Theyll need a digital file of your design, which can be produced using software such as Adobe Illustrator or CorelDRAW.

When it comes to materials, enamel pins are typically made from metal, such as brass or iron, which gives them durability. Enamel, a hard-wearing paint-like substance, is then applied to the surface of the pin to bring the design to life. There are different types of enamel pins available, such as soft enamel and hard enamel, each offering its own unique look and feel.

Once you have your design, material, and desired pin type in mind, the next step is to find a factory or manufacturer that can help bring your pin to life. There are many manufacturers available who specialize in enamel pin production, and it’s important to find one that meets your specific needs and budget. Some may only offer a limited number of colors, while others may be able to provide a wide range of customization options.

- How To Design Enamel Pins Step By Step Guide

- Step 1: Plan Your Design

- Step 2: Choose Your Materials

- Step 3: Bring Your Design to Life

- Step 4: Find a Manufacturer

- Step 5: Order a Mock-Up Pin

- Step 6: Upgrade for Durability

- Step 7: Production Time

- Step 8: Receive Your Enamel Pins

- How to make enamel pins

- Decide How Many Enamel Pins You Want To Produce

- The requirements and tools to mock up an enamel pin design

- Paint Colors

- Customizability

- Durability

- Affordability

- Upgrade With Hard Enamel Pins

- Sources

- Video:

- how to make enamel pins at home

How To Design Enamel Pins Step By Step Guide

Enamel pins are a popular accessory that many people love to collect and wear. Whether you want to create pins for yourself or as a business venture, designing enamel pins is a fun and creative process. Here is a step by step guide to help you bring your pin design to life:

Step 1: Plan Your Design

Before you start creating your enamel pin, it’s important to plan and visualize your design. Think about the message or theme you want to convey through your pin. Consider the colors, shapes, and additional customizability you want to incorporate into your design. Sketching your ideas on paper or using digital tools can help you create a clear vision for your pin.

Step 2: Choose Your Materials

Enamel pins are typically made from metal. The most common materials used are iron and brass, although other metals such as copper can be used as well. Each metal has its own characteristics and durability, so choose the material that best suits your requirements.

Step 3: Bring Your Design to Life

Once you have your design and material decided, it’s time to create a digital file of your design. You can use design software such as Adobe Illustrator or Photoshop to create a vector file. This file will then be used by manufacturers to produce your enamel pins.

Step 4: Find a Manufacturer

There are many manufacturers that specialize in producing enamel pins. Research different manufacturers to find the one that matches your needs. Consider factors such as affordability, production time, and the quality of their work. Look for manufacturers that have a wide variety of enamel pin styles and colors available.

Step 5: Order a Mock-Up Pin

Before placing a large order, it’s a good idea to order a mock-up pin first. This will give you a physical sample of how your design will look as an enamel pin. You can make any necessary adjustments to the design or coloring at this stage.

Step 6: Upgrade for Durability

If you want your enamel pins to be more hard-wearing, you can upgrade the material and the production process. For example, some manufacturers offer hard enamel pins which have a more polished and durable finish compared to soft enamel pins.

Step 7: Production Time

Once you’re happy with the mock-up pin, you can proceed with placing your order. Production time can vary depending on the manufacturer and the quantity of pins you’re ordering. Be sure to discuss the timeline with the manufacturer and factor that into your planning.

Step 8: Receive Your Enamel Pins

After the production process is complete, you will receive your enamel pins. Check for any defects or issues and make sure the pins meet your expectations. If everything looks good, you can now start sharing or selling your pins!

Designing enamel pins allows creatives to showcase their artwork and create unique accessories for themselves or others. It’s a combination of hand-drawn or digitally created designs that are then produced by a factory. Enamel pins are known for their high-quality and hard-wearing surface, giving them durability and longevity. No matter what your design idea is, there are various ways to produce enamel pins and bring your vision to life.

How to make enamel pins

Enamel pins have become a popular accessory for people of all ages. They are a small and affordable way to add a touch of personalization to your outfits or accessories. Creating enamel pins can be a fun and creative process that allows you to bring your own designs to life. Here’s a step-by-step guide on how to make enamel pins:

Step 1: Designing your pin

The first step in creating enamel pins is to come up with a design. You can either hand-draw your design or use digital tools such as Adobe Illustrator or Photoshop to create a high-quality file. Ensure that your design meets the specifications required by the manufacturer you choose to work with.

Step 2: Choosing a manufacturer

There are many manufacturers out there that can produce enamel pins, so it’s important to do your research and find one that meets your requirements. Look for manufacturers that offer high-quality pins, a variety of customization options, and good customer reviews. You may also want to consider their production time and pricing.

Step 3: Mock-up your design

Before placing a large order, it’s a good idea to create a mock-up of your design. This will give you an idea of how the finished pin will look and allow you to make any necessary adjustments. You can use a design software or simply sketch it out on paper.

Step 4: Placing your order

Once you are happy with your design and have decided on a manufacturer, you can place your order. Be sure to communicate your design, colors, and any additional requirements to the manufacturer clearly.

Step 5: Production

After placing your order, the manufacturer will begin the production process. They will use a combination of metal, enamel, and paint to create your enamel pin. Enamel pins are hard-wearing and durable, making them a long-lasting accessory.

Step 6: Upgrading the surface

If you want to bring your pins to the next level, you can opt for additional extras such as glitter, glow-in-the-dark elements, or specialty finishes. These upgrades can add a unique touch to your pins and make them stand out even more.

Step 7: Quality assurance

Once the pins are produced, the manufacturer will perform quality checks to ensure that each pin meets their standards. This is done to ensure that the pins are durable and the colors are vibrant.

Step 8: Packaging and delivery

After the quality assurance checks, the pins will be packaged and delivered to you. Depending on the manufacturer, there may be different packaging options available, such as individual plastic bags, backing cards, or custom packaging.

Step 9: Enjoy your pins

Once you receive your pins, you can start enjoying them! Enamel pins make great accessories for jackets, bags, hats, and more. They can also be great for promotional purposes or as collectible items.

Now that you know how to make enamel pins, you can get started on your own pin-making journey. Whether you’re a designer looking to bring your artwork to life or someone who wants to add a personal touch to their belongings, enamel pins offer endless customizability and creativity.

Decide How Many Enamel Pins You Want To Produce

When it comes to creating enamel pins, one of the first things you’ll need to decide is how many you want to produce. The number of pins you plan to make will affect various aspects of the production process, including cost, customization options, and lead time.

If you’re a small designer or artist, you might only want to produce a small number of pins to test the market or for personal use. On the other hand, if you’re planning to sell enamel pins or need them for a larger event or promotion, a larger quantity might be necessary.

Manufacturers of enamel pins typically offer different price tiers or quantity discounts, so ordering a higher quantity can sometimes result in lower costs per pin. However, keep in mind that producing a large number of pins also means a larger upfront investment and higher storage requirements.

Another factor to consider is customizability. Some manufacturers may have limitations on the number of colors, size, or design complexity for larger orders. If you have a specific design in mind that requires multiple colors or intricate details, make sure to check with the manufacturer about their capabilities before deciding on the quantity.

Moreover, the production process for enamel pins also requires additional time for larger quantities. Each pin is made individually, and the manufacturing process includes steps like creating a digital file, drawing a mock-up, applying colors, and ensuring durability. The more pins you order, the longer it will likely take for them to be produced and delivered.

Lastly, think about your budget and affordability when deciding how many pins to produce. While ordering a larger quantity may provide cost savings, it’s important to make sure that you can afford the upfront investment and have a plan for how to sell or distribute the pins once they are available.

In summary, deciding how many enamel pins you want to produce requires considering factors such as budget, customizability, lead time, and your specific requirements. It’s important to conduct research, compare different manufacturers, and work with them to ensure that your enamel pin design is produced to your satisfaction.

The requirements and tools to mock up an enamel pin design

When it comes to creating your own enamel pin design, there are certain requirements and tools that you will need to ensure a successful mock-up. These requirements and tools will help you bring your vision to life and ensure that your design is of high-quality.

Firstly, you will need a digital file of your design. This is the most crucial step, as it will be used by the manufacturer to produce your enamel pin. Make sure you have a high-resolution file that can be easily scaled to the desired size.

Next, you will need a variety of tools to work with. One of the most commonly used tools is a pin mock-up template. This template will help you visualize how your design will look on an actual pin. There are many different templates available, so be sure to choose one that best suits your needs.

In addition to the template, you will also need enamel paint or markers in the colors you want your pin to be. Enamel paint is the most common type of paint used for enamel pins, as it provides a hard-wearing surface that is resistant to chipping and fading.

If you want to add any additional details or customizability to your pin design, you may also require other tools such as small brushes or fine-tipped markers. These tools will allow you to add intricate details or additional colors to your design.

While it is possible to create a mock-up design by hand, many creatives prefer to use digital tools to ensure accuracy and efficiency. There are a number of digital mock-up tools available that can help you bring your design to life. These tools allow you to easily add and adjust colors, shapes, and other design elements.

When choosing your enamel pin manufacturer, it is important to ensure their high-quality materials and production process. Enamel pins are typically produced using metal, so it’s important to choose a manufacturer that can provide high-quality metal pins.

Lastly, don’t forget to consider the affordability of your enamel pin design. While some pin designs may require extras such as glitter or multiple colors, others can be produced with a simple design. Decide what extras you want for your pin and make sure to find a manufacturer that can affordably produce your design.

In conclusion, when planning to mock up an enamel pin design, it’s important to have the right tools and requirements in place. This includes a high-resolution digital file, a pin mock-up template, enamel paint or markers, and other tools that will help you bring your vision to life. By ensuring these requirements are met, you can create a high-quality enamel pin design that stands out from the rest.

Paint Colors

When it comes to creating enamel pins, one of the most important steps is choosing the right paint colors. Paint colors not only bring your design to life but also ensure that your pins are eye-catching and attractive to people. Whether you’re planning to use digital or hand-drawn artwork, there are a variety of paint colors available to help you achieve the desired look.

Enamel pins are often produced using hard-wearing enamel paint, which is applied to a metal surface. This type of paint comes in many different colors and gives your pins durability and a high-quality finish. Many manufacturers offer a wide range of paint colors, allowing you to customize your pins to suit your design requirements and bring your vision to life.

When choosing paint colors for your enamel pins, it’s important to know what you’re looking for. If you want to create a design with multiple colors, it’s best to work with a designer who can help you mock up your artwork and guide you through the process. They’ll know what colors work well together and how to ensure that the colors you choose will be vibrant and long-lasting.

Although there are many paint colors available, it’s worth noting that not all colors are created equal. Some colors may require additional coats or may not be as hard-wearing as others. It’s important to consider the durability of the paint you choose, especially if you’re planning to produce a large number of pins or if the pins will be subject to wear and tear.

Furthermore, the customizability of paint colors can vary depending on the manufacturer. Some manufacturers may offer a wider range of colors and finishes, while others may only have a limited selection. If you have a specific color in mind, it’s worth checking with the manufacturer to ensure that they can produce that color.

Enamel pins are a popular choice among creatives, and their affordability makes them a great option for those looking to upgrade their artwork. Whether you’re a professional artist or just starting out, enamel pins offer a unique way to showcase your work and bring your designs to life. With the wide variety of paint colors available, you can choose the ones that best represent your style and make your pins stand out.

In conclusion, when creating enamel pins, paint colors play a crucial role in bringing your design to life. The right colors can make your pins more attractive, durable, and eye-catching. With the wide range of options available, you can confidently choose the paint colors that best match your design requirements and create pins that are unique and appealing.

Customizability

When it comes to creating enamel pins, customizability is key. Enamel pins offer a wide range of options for you to customize your design to meet your specific preferences. From colors and materials to extras and sizing, there are many ways to make your pins truly unique.

One of the first decisions you’ll need to make is choosing the colors for your enamel pins. Enamel pins can be painted with a variety of different colors, allowing you to bring your design to life. Whether you want to go with a simple monochromatic design or a vibrant and colorful one, the choice is up to you. Additionally, there are different types of enamel, such as soft enamel and hard enamel, each offering their own unique finish.

Enamel pins are typically made using metal as the base material. This metal surface serves as a canvas for the applied enamel, giving your design a durable and high-quality finish. However, there are also other materials available, such as wood or acrylic, if you’re looking for something different.

In order to create your enamel pin design, you’ll likely need the help of a digital designer or illustrator. They’ll be able to take your idea and turn it into a digital file that can be used in the production process. This step is crucial to ensure that your design meets the requirements of the pin manufacturers. If you’re not familiar with digital design tools, there are many online resources and tutorials that can help you get started.

Once you have your design file ready, you can then place an order with a pin factory. There are many pin manufacturers out there, ranging from small-scale businesses to large factories. It’s important to do your research and choose a manufacturer that can meet your specific needs.

Customizability also comes into play in terms of extras and upgrades. The pin manufacturers offer a number of additional features that you can add to your pins, such as different types of backing pins, glitter, glow-in-the-dark elements, and more. These extras can add an extra touch of uniqueness to your pins and make them stand out.

When planning your enamel pin design, it’s important to consider both the aesthetics and the practicalities. Enamel pins are meant to be worn and displayed, so durability is key. It’s important to choose high-quality materials and ensure that your design will withstand the test of time.

Overall, customizability is one of the key features of enamel pins. They allow creatives and people with various design skills to bring their ideas to life. Whether you want to create a mock-up of a pin design or go straight to production, there are many ways to make your pins unique and personalized.

Durability

When it comes to creating enamel pins, durability is a key factor to consider. Your design may be hard-wearing, but there are additional steps you can take to ensure that your pins will last a long time.

First and foremost, it’s important to use high-quality materials for your pins. This includes the enamel paint, which comes in a variety of colors and gives your pins their vibrant and eye-catching appearance. The metal used for the pin itself should also be of a high quality, as this will ensure that it can withstand daily wear and tear.

Many manufacturers offer a wide range of customization options for enamel pins, but keep in mind that certain extras may require additional planning and cost. If you want to add steps such as an upgraded surface or multiple colors, be aware that this may require more time, resources, and potentially a higher budget.

Before producing your pins, it’s a good idea to create a digital mock-up or design file. This will allow you to see how the pin will look and make any necessary adjustments before placing an order with the factory. It’s important to know what you want your pin to look like, as well as any specific design requirements or limitations that may exist.

There are a few different ways to bring your pin design to life. Some people prefer to work by hand, using traditional tools and techniques to create their pins. Others may opt for a more digital approach, using software to create their design and then having it applied to the pin surface.

Metal pins tend to be the most popular and hard-wearing option. However, there are other materials available such as plastic or wood, which can also be used to produce enamel pins. Each material has its own benefits and drawbacks, so it’s important to consider what will work best for your design and budget.

When it comes to durability, remember that not all pins are created equal. By using high-quality materials, carefully planning your design, and ensuring that your pin meets your specific requirements, you can create a pin that will stand the test of time.

Affordability

When it comes to creating enamel pins, affordability is an important factor to consider. You may be wondering how much it will cost to bring your design to life and produce a pin. Fortunately, there are various sources available that offer different options to fit your budget and requirements.

If you’re a designer and want to make a small number of pins or have a limited budget, then customizability is key. There are manufacturers out there who offer affordable options for producing enamel pins. They’ll likely require you to provide a digital file of your design, and they can help with additional tools and materials if needed.

One way to ensure affordability is by opting for soft enamel pins instead of hard enamel. Soft enamel pins are easier to produce and usually cost less. The process involves using a mold and hand-painting each color onto the pin’s surface. This method allows for a wide variety of colors and gives the pin a slightly raised texture.

If you’re on a tight budget, you can also consider ordering a small number of pins. Most manufacturers have a minimum order requirement, but this can vary. By placing a smaller order, you can reduce the overall cost.

Another way to keep costs down is by designing your pin with a limited number of colors. The more colors you have, the more paint and time it takes to create the pin. By simplifying your design and using fewer colors, you can lower the production costs.

Keep in mind that affordability doesn’t necessarily mean sacrificing quality. While there are certainly high-quality enamel pins available, there are also lower-cost options that can still be durable and hard-wearing.

Overall, when planning your enamel pin project, be sure to consider factors such as design, customizability, materials, colors, and order quantity to find the right balance between affordability and your vision for the pins.

Upgrade With Hard Enamel Pins

If you’re a designer or a creative looking to add a touch of sophistication to your custom pin designs, upgrading to hard enamel pins is the way to go. These high-quality pins are produced using an enameling process that gives them a smooth, hard-wearing surface. In this guide, we’ll take you through the steps of how to create enamel pins, although upgrading to hard enamel adds an additional level of durability and a polished finish to your pins.

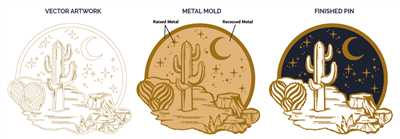

When it comes to the production process, hard enamel pins are made using metal molds. The pins are first designed digitally, and the design file is then sent to a factory where the pins are manufactured. The metal mold is used to shape the pin and an enamel paint is applied to fill the recessed areas of the design. Multiple colors can be used in this process to bring your design to life. Once the paint has been applied, the pins are fired at a high temperature to make the enamel hard and durable. This process ensures that your pins will last a long time and withstand daily wear.

One of the advantages of upgrading to hard enamel pins is the wide range of customization options available. Unlike soft enamel pins, which have a slightly raised surface, hard enamel pins have a flat, smooth surface. This makes them ideal for designs that require fine details and intricate patterns. The smooth surface also allows for a glossy finish, giving your pins an extra touch of sophistication.

Although hard enamel pins are typically more expensive than soft enamel pins, they offer a number of benefits that make them worth the investment. Hard enamel pins are known for their durability and long-lasting quality, making them a great choice if you want a pin that will withstand the test of time. Additionally, the smooth surface of hard enamel pins gives them a high-end look and feel, making them perfect for use as promotional items or as premium pieces of merchandise.

When ordering hard enamel pins, you’ll likely need to work with a manufacturer who specializes in producing this type of pin. Many manufacturers offer a variety of pin styles and materials to choose from, allowing you to find the perfect pin for your needs. They’ll also help you through the design process, ensuring that your pin meets all your requirements. Whether you want a small pin or a large one, a simple design or a complex one, a good manufacturer will be able to guide you through the process and produce a pin that you’ll be proud to wear or sell.

So, if you’re looking to upgrade your pin game and take your designs to the next level, consider upgrading to hard enamel pins. They offer a wide range of colors, a smooth and durable surface, and a high-quality finish that is sure to impress. Whether you’re a designer or a creative, hard enamel pins are a great way to add a touch of sophistication to your work.

Sources

Creating custom enamel pins is a small but highly popular market, and there are a variety of digital sources available to help you bring your unique design to life. Whether you’re an experienced designer or just getting started, these sources can assist you in creating high-quality pins that meet your specific requirements.

One of the most common sources for custom pins is to work with an enamel pin factory. These factories have the tools and expertise to produce enamel pins in a wide range of colors and designs. They can help you upgrade your design file to ensure it can be produced as a pin. Once you’ve decided on a design, you can then place an order with the factory, who will create a mock-up of your pin for approval before production begins.

While many people may be familiar with enamel pins that require hand-painted details, there are also other ways to create custom pins. Some manufacturers offer a digital print process that allows for a wide range of colors and customizability. This process gives designers the ability to produce highly detailed and colorful pins that are hard-wearing and durable.

When it comes to materials, enamel pins are typically made from metal such as brass or iron. The metal is then coated with a layer of enamel paint, which is applied in multiple steps to ensure durability and vibrant colors. This process helps to create pins that can withstand everyday wear and tear.

In addition to the pin itself, there are also a number of additional extras that you can consider. Some manufacturers offer different types of clasps, backing cards, and packaging options that can help enhance the overall presentation of your pins. These extras can be a great way to upgrade your pins and make them stand out.

It’s important to know that enamel pins come in a wide range of sizes, from small and delicate designs to larger and more intricate pieces. Whatever your creative vision, there’s likely a pin size that will work for you.

When planning your enamel pin design, it’s also important to consider the surface that the pin will be applied to. Some surfaces, such as fabric or soft materials, may require additional steps or adhesives to ensure the pin stays in place. Other surfaces, such as hard metals or materials, may not require any additional steps.

In conclusion, there are many sources available to help you create enamel pins that meet your unique design requirements. Whether you choose to work with a factory or explore digital printing options, there’s a wide range of tools and resources at your disposal. So, if you’re a creative looking to make your mark in the world of enamel pins, this guide on how to create enamel pins will surely help you get started!