When it comes to running a business, we’ve all had to deal with the tedious task of managing inventory. Selecting the right barcode system can make all the difference in staying organized and efficient. With globally standardized barcodes, you can easily label your products, track your inventory, and ensure accurate scanning through the barcode system.

So, how do you get barcode details for your business? There are several methods you can use to add barcodes to your products and assets. One option is to create your own barcodes based on industry standards. The most common type of barcode is the GTIN (Global Trade Item Number), which is used worldwide for product identification. But make sure to test the quality of your barcode symbols before printing labels.

If you’re not looking to create your own barcodes, you can also use a mobile app or barcode generator to quickly and easily get barcode details. There are many free barcode apps available that provide standardised barcode information, such as the barcode GTIN and label position. These apps can be a handy tool for businesses of all sizes, whether you’re selling products online or in a brick-and-mortar store.

Another option is to use a barcode verifier, which is a device that checks the quality and readability of a barcode. By using a barcode verifier, you can ensure that your barcodes meet industry standards and will be scannable by other businesses. This is particularly important if you plan to sell your products through other retailers or participate in a barcode-based tracking system.

- Selling a product starts with a GS1 barcodeGTIN

- How Do Businesses Use Barcodes

- Inventory Management

- Asset Tracking

- Product Labeling and Selling

- Integration with Business Systems

- Quality and Testing

- Creating an interface for barcode scanning

- Add a barcode field to the form

- Build a barcode quality plan

- 1. Define your barcode requirements

- 2. Select a barcode verifier

- 3. Add barcode details to your product information system

- 4. Implement a barcode scanning system

- Video:

- How to Create Barcodes in Excel (The Simple Way)

Selling a product starts with a GS1 barcodeGTIN

When it comes to selling products, having a standardised barcode is crucial. That’s where the GS1 barcodeGTIN comes in. GS1 is a global organisation that sets the standards for barcode use in the business world. With their barcodeGTIN, you can easily plan, create, and integrate barcode details into your products for better inventory tracking, quality control, and returns management.

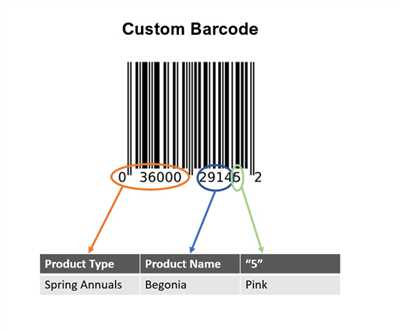

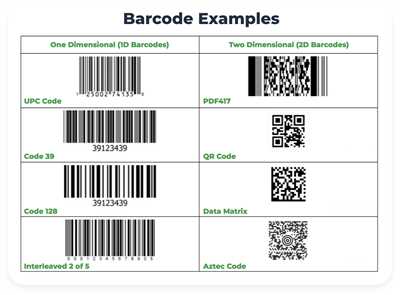

GS1 barcodes use a set of symbols to represent different information about a product, such as its type, field, and even its contents. It’s an open and globally recognised barcode system that businesses across the world rely on. By using GS1 barcodes, you can ensure that your product details are accurate, and you can streamline various processes, from inventory management to asset tracking.

To get started with GS1 barcodeGTIN, you first need to select the appropriate barcode type based on your business needs. GS1 offers different types of barcodes, such as EAN, UPC, ISBN, and more. Once you have selected the barcode type, you can create your barcode using GS1’s online interface or by using third-party barcode printing software.

When creating a GS1 barcode, you need to provide the necessary information for your product, such as its name, description, and any additional details required for tracking and inventory purposes. You also need to make sure that the barcode is of high quality, as a poor-quality barcode may not scan correctly.

After creating your barcode, you can print it on your product label, ensuring that the label position follows the standards set forth by GS1. This will help in easy scanning and readability of the barcode.

One important step in using the GS1 barcode system is to verify the barcode’s contents. This can be done using a barcode verifier, which checks the accuracy and readability of the barcode. By verifying your barcode, you can be confident that the barcode contains the correct information and meets the necessary standards.

Overall, using a GS1 barcodeGTIN is a crucial step in selling your products. It provides a standardised and globally recognised way to add barcode details, allowing for seamless integration with various inventory management systems and improving overall business operations. So if you’re starting a new business or looking to improve your current barcode system, consider implementing the GS1 barcodeGTIN for true efficiency and accuracy.

How Do Businesses Use Barcodes

In today’s technology-based world, barcodes have become an essential part of business operations. They provide a quick and efficient way to track and manage inventory, assets, and products. Businesses from various industries use barcodes to streamline their processes and improve overall efficiency.

Inventory Management

One of the primary uses of barcodes for businesses is inventory management. By using barcode labels on products, businesses can easily create a database of their inventory. The barcode contains information about the product, such as its name, type, and quantity. This enables businesses to keep track of their stock levels accurately and make informed decisions about replenishment and ordering. It helps prevent excess inventory and out-of-stock situations, optimizing the supply chain.

Asset Tracking

Barcodes are also used for tracking and managing fixed assets within businesses. Whether it’s office equipment, machinery, or vehicles, businesses can affix barcodes to these assets and use barcode scanning devices to keep a record of their location, maintenance, and movement. This simplifies the process of asset management, making it more efficient and cost-effective.

For true asset tracking, businesses can use barcode labels with globally standardized GTIN (Global Trade Item Number) symbols. GTINs ensure that products can be identified and tracked uniformly across different systems and standards worldwide.

Product Labeling and Selling

Barcodes play a crucial role in product labeling and selling. By adding barcode labels to products, businesses can streamline the checkout process and enhance customer experience. When scanning barcodes, the information linked to the barcode, such as the product name, price, and other details, is retrieved, making the purchasing process faster and more accurate.

Businesses can also use barcodes in various selling methods, such as selling on online marketplaces or using mobile apps for payments. Barcodes are used to provide detailed information about the product, including its contents, manufacturer, and any certifications or standards it complies with. This helps build trust with customers and ensures transparency in product information.

Integration with Business Systems

Barcodes can be integrated with other business systems to automate processes and improve efficiency. For example, businesses can integrate barcodes with their inventory management system, allowing for seamless updates when products are scanned in or out. This reduces manual data entry errors and speeds up the process of tracking and managing inventory.

Moreover, businesses can use barcodes to create a free, open system for publishing and retrieving product details. By using GS1 barcode standards, businesses can create barcode labels that contain detailed product information, such as origin, packaging, ingredients, and more. This allows trading partners, retailers, and consumers to access product details through barcode scanning or by using a barcode verifier.

Quality and Testing

Businesses can use barcodes to ensure quality and testing standards are met. By incorporating barcodes on products, businesses can link them to an inventory management system that tracks the manufacturing and expiry dates, batch numbers, and other relevant quality control information. This allows businesses to maintain quality control standards and recall products if necessary.

In summary, barcodes have become an indispensable tool for businesses in various fields. They are used to track and manage inventory, assets, and products, ensure accurate product labeling and selling, integrate with business systems, and maintain quality control standards. By leveraging barcodes, businesses can streamline their operations, reduce human errors, and improve overall productivity.

Creating an interface for barcode scanning

Barcode scanning is an essential tool for businesses that deal with a large number of products and assets. By using barcodes, businesses can easily track and manage their inventory, improve the accuracy of their data, and speed up the process of returns and exchanges.

When it comes to creating an interface for barcode scanning, there are several important factors to consider. First, you need to select the right barcode type for your business. There are various barcode standards available, such as GS1, which is a globally standardized system for barcodes.

Once you have selected the barcode type, you can start building your interface. One option is to integrate a barcode scanner into a mobile app or a web form. This allows you to scan barcodes directly into your system, without the need for manual data entry.

Next, you will need to set up the methods for barcode scanning. This includes setting the label position, verifier, and quality standards. Additionally, you may want to add an extra field to capture additional information about the product or asset, such as its expiry date or batch number.

It’s important to make sure that your interface is user-friendly and easy to use. Provide clear instructions on how to scan the barcode, and make sure that the barcode field is easily accessible. You can also consider adding symbols or visual cues to guide users in scanning the barcode correctly.

Once the barcode is scanned, the system should be able to provide the product details instantly. This includes information such as the product name, description, price, and any other relevant details. If the barcode is linked to a specific product in your inventory, the system should be able to retrieve all the associated information for that product.

For businesses that sell products online, barcode scanning can also be used to generate shipping labels. By scanning the barcode, the system can automatically retrieve the customer’s shipping information and generate a label that can be printed and attached to the package.

In addition to barcode scanning for products, businesses can also use barcodes for tracking their assets. By assigning a unique barcode to each asset, businesses can easily track and monitor the location and status of their assets. This can be particularly beneficial for businesses with a large number of assets, such as rental companies or construction firms.

Overall, creating an interface for barcode scanning can greatly streamline your business processes and improve the accuracy of your data. By using barcodes, businesses can save time and reduce errors, ultimately leading to increased efficiency and better customer service.

Add a barcode field to the form

If you want to include a barcode field in your form, you can easily do so by following these steps:

- Start by creating a form using an online form builder or by coding it yourself.

- Select the field type that allows you to add custom fields.

- Add a barcode field to your form, making sure to provide a unique name for it.

- Choose the type of barcode you want to use for your form. We recommend using GS1 standards for globally accepted and standardised barcode symbols.

- Set the field as a barcode field, and select the appropriate input type (e.g., text field, dropdown, etc.).

- Make sure to include a barcode verifier in your form to ensure the quality and accuracy of the barcode information provided by the applicants.

- If you plan on using mobile devices for scanning barcodes, make sure to test the barcode scanning integration with your form to ensure it works properly.

- Include additional fields in your form where applicants can provide details such as the asset name, publisher, free or restricted access, and other relevant information about the barcode.

- Integrate your form with an inventory tracking system or a database where you can store and manage the barcode details.

- You can also include a print button in your form, allowing users to print the barcode labels for their assets or products.

By adding a barcode field to your form, you can streamline the process of capturing and managing barcode details for your business. Whether you are selling products, tracking assets, or creating a barcode-based system, including a barcode field in your form is a simple and efficient way to provide the necessary information and ensure a true and quality standardised world of barcodes.

Build a barcode quality plan

When it comes to barcodes, ensuring their quality is crucial. A barcode is a standardized way to represent product information in a visual form that can be easily scanned and read by machines. It serves as a unique identifier for each product and enables businesses to track their inventory, improve logistics, and provide accurate information to customers.

To build a barcode quality plan, we need to start with the standardised barcode type, which in most cases is the GS1 GTIN barcode. This barcode is used globally and provides a unique identification number for each product. The GTIN barcode can be printed on labels, packaging, or directly on products themselves.

1. Define your barcode requirements

First, you need to define the requirements for your barcodes. Consider what type of products you will be selling and what information needs to be included in the barcode. For example, if you are selling books, you may need to include the book’s ISBN number in the barcode.

Next, decide on the label position and size. Make sure that the barcode is easily scannable and visible on the product or packaging. It is important to adhere to GS1 standards when creating barcodes to ensure interoperability with other businesses and systems.

2. Select a barcode verifier

Once you have defined your barcode requirements, you will need a barcode verifier to ensure the quality of your barcodes. A barcode verifier is a device or software that checks if the barcode meets the required standards and can be easily scanned. This step is crucial as it helps to avoid potential issues such as scanning errors or returns due to unreadable barcodes.

There are different barcode verification methods available, ranging from handheld verifiers to mobile apps. Select the method that best suits your business needs and budget.

3. Add barcode details to your product information system

Now that you have created high-quality barcodes, you need to add the barcode details to your product information system. This system serves as a central database for all your product information, including the barcode, product description, price, and other relevant details.

Ensure that your product information system is capable of integrating with your barcode printing system, so that the barcode details can be automatically generated and printed on the labels or packaging.

4. Implement a barcode scanning system

To make sure that the barcode quality plan is effective, implement a barcode scanning system. This system allows you to scan the barcodes during various stages of your business processes, such as inventory management, asset tracking, and returns handling.

Make sure that the barcode scanning system is user-friendly and provides accurate and real-time information. Test the system thoroughly to ensure its reliability.

By following these steps, you can build a barcode quality plan that will help you create and use high-quality, scannable barcodes for your products. This will ensure smooth operations, accurate data, and satisfied customers!