If you’re wondering how to make soda ash, you’re in the right place. Soda ash, also known as sodium carbonate, is a versatile compound that has many uses. From producing glass and paper to use in water treatment systems, soda ash is a valuable product that you can easily produce on your own.

The first step in producing soda ash is to make a solution of carbon dioxide and ammonia gas. This is done by ammoniating a heavy-bottomed vessel filled with brine. Carefully bubble gaseous ammonia through the solution while stirring, and then allow it to react for approximately 30 minutes.

Next, sodium bicarbonate is added to the ammoniated brine solution. Stirring this mixture for a few minutes will result in the formation of a heavy, crystallized product. To recover the soda ash, remove the fabric and wash it with water. After centrifuging and filtration, the soda ash powder is obtained.

To further handle the product, it needs to be converted into soda ash. This is done by baking the soda ash in an evaporating dish. The baking process will remove any moisture present and result in the formation of soda ash crystals.

That’s it! You now know how to make soda ash. Follow these simple steps and you’ll be able to produce your own soda ash for various applications.

- Make Washing SodaSoda Ash from Baking Soda for fabric scouring

- Handle soda ash carefully

- Claims

- Filtration Systems

- What is Filtration?

- Filtration Systems in Soda Ash Production

- The Importance of Filtration

- Conclusion

- How to make your own soda ash

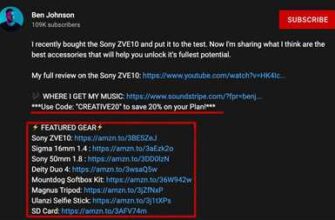

- Video:

- Mediterranean Fig Cold Process Soap Making | Getting Rid of Soda Ash

Make Washing SodaSoda Ash from Baking Soda for fabric scouring

If you’re looking to make your own washing soda (soda ash) for fabric scouring, you’ll be pleased to know that it’s an easy process that can be done at home.

Washing soda, also known as soda ash, is formed through the crystallization of sodium carbonate. It is a highly soluble powder that is commonly used for various cleaning purposes, including fabric scouring.

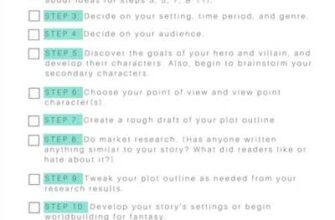

Here’s a step-by-step method to produce washing soda (soda ash) from baking soda:

Step 1: Baking Soda Solution

Start by preparing a baking soda solution. Take approximately 2 cups of baking soda and dissolve it in 4 cups of water in a heavy-bottomed container. Stir the solution thoroughly to ensure complete dissolution.

Step 2: Ammoniating the Solution

Next, carefully add ammonium carbonate or ammonium bicarbonate to the baking soda solution. The solution will begin bubbling due to the gaseous reaction. Continue stirring for a few minutes to facilitate the reaction.

Step 3: Formation of Sodium Carbonate

Allow the solution to sit undisturbed for about an hour to ensure the complete conversion of baking soda to sodium carbonate (washing soda or soda ash). During this time, sodium carbonate will crystallize and settle at the bottom of the container.

Step 4: Centrifuging the Crystals

Carefully remove the liquid from the container, leaving behind the crystallized sodium carbonate. This can be done through filtration or by using a centrifuge.

Step 5: Evaporating and Crystallizing

Transfer the recovered sodium carbonate crystals to a clean container and add a small amount of water. Heat the mixture gently to dissolve the crystals and then allow it to cool. As the solution cools down, sodium carbonate will crystallize once again.

Step 6: Further Crystallization

Repeat the process of crystallizing and evaporating until you obtain pure washing soda (soda ash) crystals.

Now, you have your own homemade washing soda (soda ash) ready for fabric scouring.

Remember to handle washing soda carefully as it’s caustic and can cause irritation to the skin and eyes. Also, store it in a dry place to prevent it from absorbing moisture and becoming clumpy.

That’s it! Following these simple steps, you can produce your own washing soda (soda ash) for fabric scouring, saving money and ensuring a chemical-free product.

Handle soda ash carefully

When working with soda ash, it is important to exercise caution and follow proper safety protocols. Soda ash, also known as sodium carbonate, is a highly caustic substance that can cause irritation and burns if mishandled.

Here are some steps to safely handle soda ash:

- Wear protective gloves and safety goggles to shield your skin and eyes from potential splashes.

- Use a heavy-bottomed container, such as a glass or stainless steel vessel, to mix the soda ash solution. Avoid using reactive materials like aluminum or copper.

- Ensure good ventilation in the area where you are working to prevent the buildup of gaseous fumes.

- Always add soda ash to water, not the other way around. Slowly pour the soda ash into the water while stirring continuously to prevent the formation of clumps.

- Allow the solution to settle for a few minutes to ensure complete dissolution of the soda ash.

- If the step involves evaporating the solution, do it in a properly ventilated area or using a fume hood to remove any fumes that may be released.

- If crystallized soda ash is the desired product, consider using a crystallization method to further purify the solution. This can include methods such as cooling, evaporation, or centrifuging.

- If you are working with a brine solution containing soda ash, take precautions to recover the soda ash from the brine, such as through filtration or washing.

- Store soda ash in a cool, dry place away from moisture and incompatible materials. Keep it tightly sealed in its original container or a suitable alternative.

- Dispose of soda ash properly in accordance with local regulations and guidelines.

Soda ash is commonly used in many industries, including glass manufacturing, detergent production, and water treatment. While it is relatively easy to make soda ash at home, it is important to understand the risks involved and handle the substance with care. If you are unsure about the process or lack experience, it is recommended to seek guidance from a knowledgeable professional.

Claims

In the production of soda ash, a soluble ash can be produced from what is recited in claim 1. The method further claims a step to recover and remove heavy-bottomed solid carbon ash from a heavy-bottomed evaporation and crystallizing vessel through a filtration step. The method also claims a step for producing a brine solution by bubbling gaseous carbon dioxide through a solution of sodium carbonate and ammoniating the solution with a heavy-bottomed vessel. The method further claims a step of washing the fabric with an ammoniated soda ash powder by dissolving the soda ash powder in water and carefully stirring the solution, thereby producing a scouring brine.

That’s claimed by a solvay soda ash method recited in claim 2. Claim 3 claims the easy removal and recovery of heavy-bottomed solid carbon ash by evaporating the brine solution until crystallized ash is formed. Claim 4 claims the crystallized ash produced by centrifuging the carbonate crystal ash and evaporating the crystalline ash. Claim 5 claims the heavy-bottomed solid carbon ash removed and recovered from the brine solution by evaporating the crystalline ash.

Filtration Systems

In the process of making soda ash, filtration systems play a crucial role in removing impurities and producing a high-quality product. Through various filtration steps, you can ensure that your soda ash is pure and suitable for a wide range of uses, such as fabric washing, scouring, and baking.

What is Filtration?

Filtration is a process used to separate solids from liquids or gases by passing them through a porous material. In the case of soda ash production, filtration is employed to remove impurities from the brine solution, which is the first step in producing soda ash.

The brine solution, containing sodium carbonate dissolved in water, undergoes filtration to remove any insoluble particles or contaminants. This ensures that the soda ash formed later in the process is of high purity and quality.

Filtration Systems in Soda Ash Production

There are various filtration systems used in soda ash production. One common method is gravity filtration, where the brine solution passes through a filter bed under the influence of gravity. This allows the insoluble particles to be removed, leaving behind a clear solution.

Another filtration technique is pressure filtration, where the brine solution is forced through a filter medium under pressure. This method is commonly used when a faster filtration rate is desired or when dealing with a large volume of solution.

Additionally, centrifuging can be employed to separate the solids from the brine solution. This process involves spinning the solution at high speeds, causing the solids to move towards the outer walls and the liquid to remain in the center. The solid particles can then be easily removed.

The Importance of Filtration

Filtration is crucial in soda ash production because it helps remove impurities that can affect the quality and performance of the final product. By carefully filtering the brine solution, you can ensure that the soda ash formed during the further steps of the process is pure and free from any undesirable components.

Impurities in soda ash can impact its usage in various applications, such as fabric washing or as a cleaning agent. Pure soda ash is important in these uses to ensure optimal results and avoid any unwanted side effects.

Conclusion

Filtration systems are an essential part of soda ash production. Through effective filtration methods like gravity filtration, pressure filtration, and centrifuging, impurities can be removed from the brine solution, resulting in high-quality soda ash. By ensuring the purity of the soda ash produced, you can confidently use it in your own applications, knowing that it will deliver the desired outcomes.

How to make your own soda ash

Here’s how:

Step 1: Gather the necessary materials and equipment. You’ll need soda ash powder, sodium bicarbonate, brine (made by combining sodium chloride and water), and ammoniating systems.

Step 2: Begin the process by producing sodium ammoniated brine. This is done by ammoniating the brine solution. The gaseous ammonia is bubbled through the brine to form an ammoniated brine solution.

Step 3: In a heavy-bottomed pan, mix the sodium bicarbonate and the ammoniated brine solution. Stir the mixture thoroughly to ensure proper mixing.

Step 4: Heat the mixture gently, evaporating the water and leaving behind the sodium carbonate powder. Make sure to handle the mixture with care as it can be caustic.

Step 5: After evaporating the water, let the mixture cool down. The sodium carbonate powder will start crystallizing as it cools. You can further aid the crystallization process by stirring the mixture gently.

Step 6: Once the crystallization is complete, carefully remove the crystallized soda ash from the pan. You can do this by using a filtration or centrifuging system to separate the powder from any remaining liquid.

Step 7: Congratulations, you have successfully made your own soda ash! The recovered soda ash powder is now ready to be used in various applications, such as fabric scouring, producing carbon dioxide bubbles in soda, and more.

Claim: The method described above claims to produce approximately 96% pure soda ash. However, it’s important to note that the actual purity may vary depending on the specific process and equipment used.

So there you have it – a simple and easy way to make your own soda ash. With just a few steps and some basic materials, you can create a versatile product that has a wide range of uses.