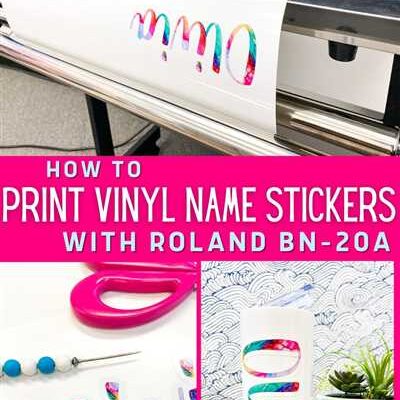

Stickers and decals have become a popular choice for businesses and individuals alike. Whether you want to create custom stickers for your home or need a high-end product for your business, printing vinyl stickers gives you the freedom to design and customize as you please.

When it comes to printing vinyl stickers, there are a few things you need to know. First, you’ll need the right materials. Vinyl is the ideal base for stickers as it is durable and can withstand different surfaces. You can choose between matte or glossy finishes depending on the look you want to achieve.

Next, you’ll need a printer that can handle vinyl stickers. If you’re printing at home, make sure your printer is capable of printing on vinyl. If not, you can always use a professional printing service that offers vinyl sticker printing. This might cost you a bit more, but it ensures a high-quality finish.

One of the key steps in printing vinyl stickers is choosing the right adhesive. Adhesives come in different options, such as permanent and removable. The choice depends on how long you want the sticker to stay stuck and whether you want it to be easily removable without leaving any residue.

Once you have all the materials, it’s time to design your sticker. You can use design software such as Adobe Illustrator or Photoshop to create your sticker. Make sure to create your artwork in the CMYK color format, as this is the standard for printing. It’s also a good idea to convert any text to outlines to avoid font issues.

When your design is ready, you can proceed to the printing process. If you’re printing at home, load the vinyl sticker paper into your printer, making sure to follow the printer’s instructions. If you’re using a professional printing service, upload your design and specify any special requirements, such as metallic finish or protective coating.

Once your stickers are printed, it’s time to cut them out. You can use a cutting machine for a precise and rapid process, or simply cut them by hand if you’re only printing a few. Make sure to leave a small border around your design to ensure the sticker stays fully intact.

Finally, after the cutting process is complete, you can peel off the backing and stick your vinyl stickers wherever you please. Whether you use them for packaging, branding, or personal use, vinyl stickers are a great way to add a pop of color and personality to any surface.

In conclusion, printing vinyl stickers allows you to unleash your creativity and create unique designs for any purpose. Whether you’re a business owner looking to promote your brand or an individual looking to personalize your belongings, vinyl stickers are a versatile and cost-effective solution. Follow this step-by-step guide to ensure the best result possible and enjoy the process of printing your own vinyl stickers!

- Printing on Vinyl Paper Step-by-Step Guide

- Secure Checkout

- Are Vinyl Stickers Waterproof

- How To Print Vinyl Stickers

- How Much Does It Cost To Print Vinyl Stickers

- Business Logo Vinyl Stickers

- Printing Your Stickers and Decals

- Material

- Sticker Adhesives

- Different Printing Options

- The Difference Between Offset and Digital Printing

Printing on Vinyl Paper Step-by-Step Guide

If you want to create custom stickers or decals for your home, office, or any other space, printing on vinyl paper is a popular choice. Vinyl paper is a versatile material that can be used for a variety of purposes, including window decals, signs, labels, and more. In this step-by-step guide, we will show you how to print on vinyl paper using a digital printing process.

Step 1: Prepare your design

Before you start the printing process, you will need to have a digital design of the sticker or decal you want to create. You can use design software like Adobe Illustrator or CorelDRAW to create your design. Make sure to set the document size to the dimensions of your desired sticker or decal.

Step 2: Choose the right vinyl paper

There are different types of vinyl paper available, so it’s important to choose the one that suits your needs. Standard vinyl paper is suitable for most projects, but if you want a high-end finish or special effects like metallic or supersized stickers, you may need to use specialized vinyl paper.

Step 3: Load the vinyl paper into the printer

Once you have your design ready and the right vinyl paper, it’s time to load the paper into your printer. Most printers have a tray or slot specifically designed for loading thicker materials like vinyl paper. Follow your printer’s instructions to load the paper correctly.

Step 4: Adjust the printing settings

Before you start printing, you may need to adjust the printing settings on your computer. Make sure the print quality is set to high or the desired level, and select the vinyl paper type in the printer settings. This will ensure that the printing process produces the best results on vinyl paper.

Step 5: Print the design on vinyl paper

After you have adjusted the printing settings, you can start the printing process. Click on the print button and wait for the printer to finish printing your design on the vinyl paper. Make sure to have enough ink and paper for larger orders.

Step 6: Let the printed vinyl paper dry

Once the printing is complete, it’s important to let the printed vinyl paper dry completely before further handling or applying any additional layers. This will ensure that the ink stays secure on the vinyl surface and doesn’t smudge.

Step 7: Optional: Apply a laminate layer

If you want to give your printed vinyl stickers added durability and protection, you can apply a laminate layer. This additional layer of material will help the stickers stay stuck to various surfaces, even in outdoor conditions. Follow the instructions provided with the laminate material for the best results.

Step 8: Cut out the stickers or decals

After the printing and drying process, you can proceed to cut out the stickers or decals from the printed vinyl paper. You can use a cutting machine or a pair of scissors to achieve the desired shape and size.

Step 9: Apply the stickers or decals

Finally, it’s time to apply the printed vinyl stickers or decals to the desired surface. Clean the surface thoroughly before applying the sticker to ensure a secure adhesion. Peel off any backing material from the sticker and carefully place it on the surface. Smooth out any air bubbles or wrinkles to achieve a clean finish.

As you can see, printing on vinyl paper is a simple process that can be done with just a few steps. Whether you’re printing small custom stickers for personal use or large orders for business purposes, this step-by-step guide should help you create high-quality vinyl stickers or decals in no time.

Secure Checkout

When it comes to printing vinyl stickers, you have different options depending on your needs. One popular and widely used technology is digital printing, which gives you the freedom to upload your own custom designs and have them printed on a variety of surfaces. Another option is flexographic printing, which is commonly used for large-scale printing projects. This process uses a combination of metallic plates and ink to create the desired designs.

If you’re looking to print small or medium-sized stickers at home, a high-quality printer and the right type of paper might be all you need. However, if you want a more professional and long-lasting finish, you might want to consider using a printing service that offers laminating options. Lamination not only protects the print from fading over time, but it also gives the sticker a glossy or matte finish, depending on your preference.

Once your stickers are printed and laminated, you can then cut them into the desired shape. There are cutting machines available that can make the process much easier and save you time. However, if you don’t have access to a cutting machine, you can always cut them by hand using a pair of scissors or a craft knife.

If you want your stickers to be permanent and stick well on windows or other smooth surfaces, you might want to consider using a permanent adhesive backing. This will ensure that your stickers stay in place for a long time without peeling off.

When it comes to purchasing vinyl stickers, many online options are available. However, you should always check the security of the checkout process before making a purchase. Look for websites that have a secure checkout, indicated by a padlock symbol in the address bar. This will help protect your personal and payment information from unauthorized access.

Before checking out, take the time to review your order to make sure everything is correct. Check the quantity, size, and design of the stickers to ensure they meet your requirements. If you have any specific instructions or additional requests, make sure to communicate them to the seller before finalizing your purchase.

In conclusion, printing vinyl stickers can be a fun and creative process. Whether you choose to print them at home or use a professional service, make sure to consider all the options and requirements to achieve the best results.

Are Vinyl Stickers Waterproof

Vinyl stickers are a popular choice for many businesses and individuals who want to create custom stickers. One important question that often arises is whether vinyl stickers are waterproof.

The answer is yes, vinyl stickers are waterproof. Vinyl stickers are made from a durable material that is resistant to water and other liquids. This makes them suitable for use on a variety of surfaces, including outdoor environments. Whether you want to use vinyl stickers for your home, car, or business, you can be confident that they will stay in place and remain vibrant even when exposed to rain, snow, or other potentially damaging conditions.

Although vinyl stickers are waterproof, it’s important to note that they are not completely indestructible. Vinyl stickers can withstand exposure to water and other liquids, but they may still be affected by extreme conditions or harsh chemicals. If you want to protect your vinyl stickers from potential damage, it’s a good idea to avoid exposing them to excessive heat, abrasion, or solvents.

When it comes to printing vinyl stickers, there are different options available. If you want to print your own vinyl stickers at home, you can use a digital printer and adhesive vinyl sheets. This allows you to create custom designs and print them on vinyl that is suitable for outdoor use.

Another option is to order vinyl stickers from a professional printing service. Printing companies that specialize in vinyl stickers can offer a wider range of options, such as different adhesive types, high-end materials, and supersized stickers. They also have the technology and expertise to ensure that your stickers are printed with high quality and durability, giving you a professional finish.

One type of printing technology often used for vinyl stickers is flexographic printing. This process uses flexible plates to transfer ink onto the sticker material. It is a cost-effective and rapid printing method that is ideal for large orders. Another option is offset printing, which is a more high-end and in-depth process that gives you even more control over the colors and finish of your stickers.

When placing an order for vinyl stickers, you should consider the specific needs and requirements of your business or project. For example, if you need waterproof stickers for outdoor use, you should make sure that the adhesive used is suitable for those conditions. Similarly, if you want your logo or design to stand out, you might opt for full-color printing or a custom shape.

In conclusion, vinyl stickers are waterproof and can withstand exposure to water and other liquids. They are a versatile and durable option for both personal and business use. When choosing a printing service for your vinyl stickers, make sure to consider factors such as the printing technology used, material options, and the ability to customize your stickers to meet your specific needs. By taking these factors into account, you can ensure that your vinyl stickers are of high quality and will stay looking great over time.

How To Print Vinyl Stickers

Printing vinyl stickers has become a popular way to create custom decals for various needs. Whether you want to print smaller logo stickers for packaging or supersized designs for windows, vinyl stickers give you the freedom to create eye-catching and long-lasting decals for any surface.

There are different types of vinyl stickers available, and the choice will depend on what you need. For example, if you want waterproof and permanent stickers, you should opt for premium vinyl material. On the other hand, if you want stickers that can be easily removed without leaving any residue, you might choose a removable vinyl option.

To print vinyl stickers, you will need a printer that uses a toner-based technology, such as a laser printer. This type of printer allows you to print high-quality designs that will stay vibrant and vibrant over time.

Once you have your design ready, follow these step-by-step instructions to print your vinyl stickers:

- Secure your vinyl sticker sheet onto a cutting mat to prevent it from moving during the printing process.

- Open your design in a software program that supports vector graphics, such as Adobe Illustrator or CorelDRAW.

- Set up your design according to the specifications of your printer. Make sure to adjust the size and orientation of your design to fit the sticker sheet.

- Print a test sheet on regular paper to check the alignment and quality of your design.

- Load the vinyl sticker sheet into your printer, making sure it is correctly positioned.

- Print your design onto the vinyl sticker sheet. Make sure to use the appropriate settings for your printer to achieve the best results.

- Once your vinyl stickers are printed, allow them to dry completely before handling.

- If desired, you can laminate your vinyl stickers for extra protection. This will give them a glossy finish and make them more durable.

- Cut out your vinyl stickers using a sharp craft knife or a vinyl cutter machine. Be careful not to cut into the backing material.

- Peel off the backing material from each sticker, revealing the adhesive side.

- Apply your vinyl stickers to the desired surface, making sure to smooth out any air bubbles or wrinkles.

Printing vinyl stickers at home allows you to create custom decals for a variety of purposes. From packaging labels to window decals, vinyl stickers are a versatile and cost-effective way to enhance your branding efforts. Follow this guide to print your own vinyl stickers and unleash your creativity!

How Much Does It Cost To Print Vinyl Stickers

When it comes to printing vinyl stickers, the cost can vary depending on several factors. These factors include the size, material, laminate, and design of the stickers, as well as the quantity you need. Understanding these variables will help you determine the cost of printing vinyl stickers for your business or personal needs.

The base cost of printing vinyl stickers typically includes the cost of the vinyl material itself, as well as any adhesives or laminates that may be required. The printing process uses a special printer that uses toner to create high-quality images on the vinyl. The cost of the printer itself, as well as the cost of the toner, may also be factored into the overall cost of printing.

If you want to print custom vinyl stickers, the cost may be slightly higher as it involves additional steps such as logo uploading and the use of premium or metallic materials. Premium stickers often have a higher price due to their superior quality and durability.

Another factor that may affect the cost of printing vinyl stickers is the size of the stickers. Smaller stickers may cost less to print, while larger or supersized stickers would require more material and potentially a larger machine to print them. The cost can also be affected by the complexity of the design, as intricate or detailed designs may require more time and effort to print.

In addition to the cost of printing the vinyl stickers, there may also be additional costs associated with cutting and finishing the stickers. These processes ensure that the stickers have a clean and professional appearance and may require specialized equipment or the assistance of a printing service.

It’s important to note that the cost of printing vinyl stickers may also vary depending on the quantity you need. Printing in bulk or ordering a large quantity of stickers can often result in a lower cost per sticker, while smaller orders may have a slightly higher cost per unit.

A popular option for printing vinyl stickers is digital printing, which offers high-quality results and a wide range of customization options. Digital printing is also known for its quick turnaround time, making it a convenient choice for businesses that need stickers in a timely manner.

When printing vinyl stickers, it’s essential to choose the right material and finish for your needs. Waterproof and permanent adhesives are often preferred for outdoor use or long-term decals, while removable adhesives may be preferred for temporary or promotional stickers.

In conclusion, the cost of printing vinyl stickers can vary depending on several factors, including size, design complexity, material, quantity, and the level of customization required. Understanding these factors and working with a reputable printing service can help you determine the cost and find the best option for your business.

Business Logo Vinyl Stickers

If you’re a business owner, you know how important it is to create brand awareness and make a lasting impression on your customers. One effective way to achieve this is by using business logo vinyl stickers. These stickers can be printed and applied by yourself, or you can opt for a professional printing service to get high-quality results.

When it comes to printing vinyl stickers for your business logo, there are a few things you need to know. For example, the material you choose for your stickers will depend on your specific needs. Vinyl is a popular choice for its flexibility, durability, and ability to be stuck on various surfaces, including windows.

If you want a more permanent option, you could consider using metallic vinyl or laminating your stickers to give them a glossy finish and protect them from the elements.

The process of printing vinyl stickers involves designing your logo, uploading it to a printer or designing software, and ordering the prints. Depending on the size and type of stickers you need, the cost may vary. While smaller orders can be printed using an office printer and a regular vinyl sheet, large orders may require offset or flexographic printing, which uses a specialized machine.

Once your stickers are printed, the next step is cutting them into the desired shape. This can be done manually or using a cutting machine. You can choose to leave a border around your logo or have it cut to the exact shape.

When it comes to applying your vinyl stickers, the process is relatively simple. Make sure the surface is clean and dry, peel off the backing, and carefully stick the sticker onto the desired surface. Vinyl stickers adhere well to most surfaces and are also easy to remove without leaving any residue or damaging the surface.

One of the benefits of vinyl stickers is the wide variety of adhesives available. For example, you can choose a permanent adhesive that ensures your stickers stay in place for a long time, or a removable adhesive if you plan to change or reposition the stickers frequently.

In conclusion, business logo vinyl stickers are a cost-effective and popular way to promote your brand and make it stand out. Whether you choose to print them yourself or use a professional service, these stickers can help give your business the exposure it needs. So, why not order your own vinyl stickers today and start spreading the word about your business?

Printing Your Stickers and Decals

When it comes to printing your vinyl stickers and decals, it’s important to know all the options available to you. In this in-depth guide, we will explain the different printing technologies, materials, and techniques that you can use to create high-quality, permanent stickers for your home, business, or personal projects.

The choice of printing technology will depend on what you want to achieve with your stickers. If you’re looking for a cost-effective and easy-to-use method, digital printing is a popular option. It allows for rapid turnaround times and gives you the freedom to print custom designs on a wide range of materials.

If you’re printing large quantities or require a high-end, professional finish, offset printing may be the best choice. This traditional printing method produces consistent and vibrant results, making it ideal for packaging, labels, and more.

Regardless of the printing technology you choose, it’s essential to have the right equipment. A high-quality printing machine will ensure that your stickers come out clear, even, and long-lasting. Make sure to do your research and invest in a reliable printer that can handle the type of print jobs you have in mind.

In addition to the printing machine, you will also need the right materials. Vinyl is a popular choice for stickers and decals because it is durable, waterproof, and easy to apply. You can choose from different types of vinyl, including standard, premium, and metallic, depending on the desired look and finish.

Before printing your stickers, it’s important to prepare your design files properly. Make sure that the resolution and file format are suitable for printing. You may also need to add a bleed area and protect your designs with a waterproof layer, especially if they will be exposed to outdoor elements.

Once your design files are ready, you can upload them to the printing service of your choice and proceed with the checkout process. Many online printing services offer free templates and design assistance to help you create the perfect sticker.

When it comes to cutting your stickers, you have two options: die-cutting and kiss-cutting. Die-cutting cuts through the vinyl and the backing paper, creating individual stickers. Kiss-cutting only cuts through the vinyl, leaving the backing paper intact. The choice between the two depends on your preference and the application of the stickers.

Now that you know how to print your stickers and decals, it’s time to get started! Whether you’re creating custom stickers for your business or personal use, the right printing technology and materials will help you achieve professional-looking results.

Material

When it comes to printing vinyl stickers, one of the most important things to consider is the material used. The right material will depend on the type of sticker you are printing, whether it be for business or personal use.

Vinyl is the most commonly used material for stickers due to its durability and versatility. It is a secure and permanent material that can even withstand the outdoors without fading or peeling. Vinyl stickers are also waterproof, which is ideal for products that might come into contact with water.

There are different types of vinyl materials that can be used for printing stickers. One common type is the vinyl sticker sheet, which is a thin, flexible material that can be easily printed and cut into any shape or size. Another type is the window cling, which uses a static charge to adhere to windows and can be easily removed and repositioned.

When choosing the right vinyl material for your stickers, you should also consider the printing technology you will be using. There are two main types of printing processes: flexographic and offset. Flexographic printing is a rapid and cost-effective method that works well for large quantity printing, while offset printing is a high-quality method that gives a premium finish to your designs.

It’s important to know that different vinyl materials may require different printing methods. For example, metallic vinyl materials may need to be printed using a special metallic ink. Additionally, some vinyl materials may have a base layer that needs to be removed before printing.

In-depth knowledge about the material you are using is essential to ensure the best result. For example, if you are printing vinyl stickers for car windows, you should know that the material needs to be able to withstand the heat and UV rays from the sun without fading or peeling. On the other hand, if you are printing vinyl stickers for metal surfaces, you need a material that will stay stuck without the use of adhesives.

The material you choose will also depend on your specific needs and preferences. For example, if you want your stickers to have a glossy or matte finish, you can choose a material that will give you the desired look. You can also consider using a clear vinyl material that allows the color of the surface to show through.

In conclusion, choosing the right material for your vinyl stickers is crucial for their durability, appearance, and functionality. Understanding the different types of materials available, their uses, and how they interact with the printing process will help you make the best choice for your business or personal needs. Whether you opt for a standard vinyl sticker sheet or a specialized material, following a step-by-step guide and using the right printing technology will ensure your stickers are of the highest quality and meet all your requirements.

Sticker Adhesives

When it comes to printing vinyl stickers, one important factor to consider is the type of adhesive used. The adhesive is what allows the sticker to stay securely in place once it is applied. In this in-depth guide, we will explore the different adhesive options available and the factors you should consider when choosing the right adhesive for your sticker needs.

One popular type of adhesive for vinyl stickers is the permanent adhesive. As the name suggests, this adhesive creates a strong bond that is difficult to remove without causing damage to the surface. This makes it a great choice for stickers that need to withstand outdoor conditions or stay stuck for a long period of time.

Another option is the removable adhesive, which allows the sticker to be easily removed without leaving any residue behind. This type of adhesive is ideal for temporary stickers or if you want the flexibility to change the sticker’s placement without damaging the surface.

In addition to the adhesive type, the finish of the sticker can also make a difference. For example, if you want a premium, high-gloss finish, you might opt for a laminate layer to protect the printed design. On the other hand, if you’re looking for a more rustic or vintage feel, a matte finish might be more appropriate.

Waterproof adhesives are also available for those who need their stickers to withstand exposure to water or other liquids. This is especially important if the stickers will be used on items like water bottles or packaging that might come into contact with moisture.

One important factor to keep in mind is the type of printing used. The most common printing method for vinyl stickers is digital printing. This method allows for rapid and high-quality printing without the need for color separations. However, if you have large or supersized orders, you might consider flexographic printing as a cost-effective option.

When creating custom vinyl stickers, you have the freedom to choose the adhesive, finish, and design that best matches your business or personal needs. Whether you’re looking for a metallic finish or a sticker with your logo, knowing your options and the different adhesive types will help you make an informed decision.

In conclusion, sticker adhesives play a crucial role in the overall quality and durability of vinyl stickers. The adhesive type, laminate layer, and finish all depend on your specific needs and the intended use of the stickers. By understanding the different adhesive options and considering the factors discussed in this guide, you can ensure that your vinyl stickers are printed with the right adhesive for the job.

Different Printing Options

When it comes to printing vinyl stickers, there are several different options available to you. The right choice will depend on your specific needs and preferences. In this section, we will discuss some of the most common printing options.

Standard Printing: Standard printing is a popular choice for small orders and home use. It typically involves using a desktop printer with toner cartridges to print the stickers. While this option is cost-effective and convenient, it may not provide the same level of durability or professional finish as other methods.

Offset Printing: Offset printing is a high-end printing technology that is often used for larger orders and commercial purposes. It offers a more in-depth and precise printing process, resulting in vibrant colors and sharp details. However, offset printing requires specialized equipment and may have a longer turnaround time.

Flexographic Printing: Flexographic printing is a versatile printing method that can be used for a wide range of sticker types and sizes. It is a popular choice for orders that require a rapid turnaround time and a high volume of stickers. This printing technology is known for its ability to apply permanent adhesives to various surfaces.

Premium Printing: If you want to go the extra mile and have high-quality stickers with premium finishes, then premium printing is the way to go. This option often includes additional services such as spot UV coating, embossing, foil stamping, and more. Premium printing is typically used for special occasions, high-end packaging, or when you need to make a lasting impression.

Waterproof Printing: If your stickers will be exposed to moisture or other harsh conditions, then waterproof printing is a must. This printing method uses special materials and adhesives that can withstand water, oil, and other liquids. Waterproof stickers are perfect for outdoor use, product labels, and any application where durability is a priority.

Custom Printing: Custom printing allows you to bring your unique designs and ideas to life. Whether you have a custom logo, artwork, or specific requirements, custom printing can fulfill all your needs. Some printing services even offer free design support, allowing you to upload your own artwork or get assistance from their design team.

When choosing the right printing option for your vinyl stickers, consider factors such as the quantity and size of your order, the desired finish and durability, the type of adhesive required, and your budget. Whether you’re printing stickers for personal use or for your business, understanding these different printing options will help you make an informed decision and ensure that your stickers are printed to perfection.

The Difference Between Offset and Digital Printing

When it comes to printing vinyl stickers, there are two main methods to choose from: offset and digital printing. Both techniques have their own unique characteristics and benefits, so it’s important to understand the difference between them before deciding which one will best suit your needs.

- Offset Printing: Offset printing is a traditional printing method that uses a series of ink rollers to transfer ink onto a rubber blanket, which then presses the ink onto the vinyl sticker. This process allows for high-quality, vibrant colors and precise detail. Offset printing is typically used for large orders, as it can be more cost-effective for larger quantities.

- Digital Printing: Digital printing, on the other hand, uses a digital file that directly transfers the ink onto the vinyl sticker. This process is more flexible and can accommodate smaller orders or even one-offs without the need for a lengthy setup process. Digital printing is also capable of producing high-quality prints with vibrant colors, although the finish may differ slightly from offset printing.

While both offset and digital printing can create stunning vinyl stickers, there are a few key differences to consider:

- Cost: Offset printing is typically more cost-effective for larger orders, while digital printing can be more economical for smaller quantities.

- Turnaround Time: Digital printing is generally faster than offset printing, making it an ideal choice for rush orders or tight deadlines.

- Waterproof and Adhesive Options: Different adhesives and waterproof options are available for both types of printing, so it’s important to consider the specific requirements of your stickers.

- Design Options: With digital printing, you have the ability to easily customize and change your designs, while offset printing may require the creation of printing plates.

- Surface Compatibility: Offset printing can be used on a variety of surfaces, including paper, cardboard, and metal, while digital printing is best suited for vinyl and other smooth surfaces.

- Product Size: Offset printing can handle supersized sticker projects, while digital printing is more suitable for smaller to medium-sized stickers.

Ultimately, the choice between offset and digital printing will depend on your specific needs and preferences. If you’re unsure which option is right for you, it may be helpful to consult with a printing professional or refer to a step-by-step guide that can provide in-depth information on each printing method.

Remember to consider factors such as cost, turnaround time, design options, and surface compatibility when making your decision. Whether you’re looking to print window stickers, custom labels, or any other type of vinyl stickers, having a clear understanding of the different printing technologies can help you create the perfect product.

When you’re ready to print, make sure to provide the correct file format for your chosen printing method (JPEG, PNG, or PDF, for example) and upload your designs to the printing service. If you’re unsure about any aspect of the printing process, don’t hesitate to reach out for assistance.

Printing vinyl stickers is a secure and popular way to create eye-catching designs for windows, walls, vehicles, and more. With the right technology and adhesives, your stickers will be able to withstand the elements, while also adding a unique touch to any surface. So, whether you’re looking to print standard labels or create your own custom stickers, vinyl printing offers a highly versatile and durable solution.