Designing high-quality vinyl stickers is a fun and creative process that allows you to showcase your unique style and personality. Whether you’re looking to create a custom sticker for personal use or for your business, it’s important to understand the steps involved in the design process in order to achieve the best possible outcome. In this article, we’ll walk you through the steps of designing vinyl stickers, from selecting the right software to applying the final product.

The first step in designing vinyl stickers is to select the right software. There are many software options available, both free and paid, that offer a variety of features and tools to help you create your perfect sticker design. Some popular software options include Adobe Illustrator, CorelDRAW, and Inkscape. It’s important to choose a software that you’re comfortable with and that has the necessary tools to create the specific design you have in mind.

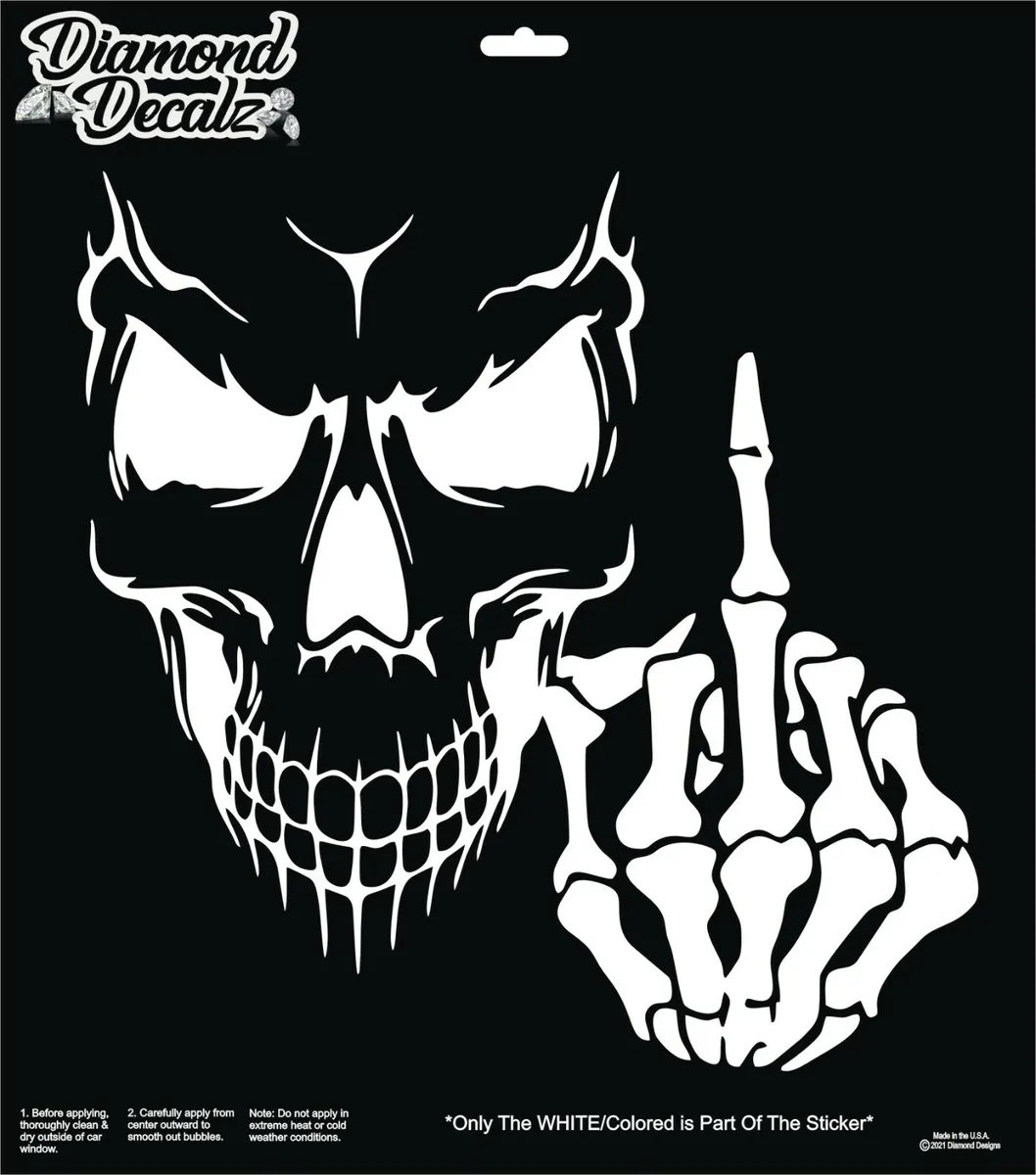

Once you’ve selected the right software, it’s time to start creating your sticker design. This is where your creativity can really shine! Whether you’re designing lettering, graphics, or a combination of both, make sure to pay attention to the details and keep in mind the specific shape and space limitations of your sticker. You can choose from a variety of pre-designed shapes or create your own custom shape. Just make sure that your design fits within the limits of the sticker size you’ve selected, and don’t forget to leave some space for the adhesive if you plan on placing the sticker on a window or other smooth surface.

After you’ve finalized your sticker design, it’s time to turn it into a reality. The next step is to order a test or pre-production run of your design. This is a crucial step because it allows you to see how your design will look on the actual vinyl material and make any necessary adjustments before placing a larger order. It’s always better to catch any potential issues during the testing phase rather than after production, as it can save you time, money, and frustration.

Once you’re happy with the test run of your design, it’s time to place your final order. The process of production and shipping will vary depending on the company you choose to work with, but most reputable vinyl sticker manufacturers offer a fast turnaround time and ship within a specific time frame. It’s important to consider the production time and shipping time when placing your order, especially if you have a specific deadline to meet.

In conclusion, designing vinyl stickers can be a great way to showcase your creativity and create a unique collection of stickers. By following the steps outlined in this article, you can ensure that you create high-quality stickers that will stand out and last for a long time. So, what are you waiting for? Get started on your vinyl sticker design today!

- Create A Custom Sticker

- Custom Vinyl Decal Information

- Vinyl Decal Application

- Other Decal Products

- Custom Vinyl Decal Colors

- Parts of Personalized Decals

- Decal Application Surface

- Decal Adhesive Details

- Decals without Minimum Quantity Limits

- Vinyl Decal Pricing

- Vinyl Decal Weathering Conditions

- Turnaround Time for vinyl decals

- Decal Ordering Expectations

- Printing the vinyl sticker

- Video:

- how I design and make stickers from home! ✿ no cricut, step by step for beginners

Create A Custom Sticker

If you want to make your own custom sticker, StickyLife is the best place to do it. With years of experience in sticker design and printing, StickyLife offers a huge variety of options to choose from. When designing your sticker, you can select the size, shape, and even the type of material that will be used.

One of the most important parts of designing a custom sticker is the artwork. You can either upload your own artwork or use the design tool within the website to create your own. If you don’t have any artwork yet, don’t worry! StickyLife offers a collection of pre-made designs that you can choose from.

Once you have selected your artwork or created your own, you can customize it further by adding text, selecting specific colors, or choosing from a variety of lettering options. StickyLife offers a wide range of options to help you make your sticker unique.

After you have completed your design, you can preview it to see how it will look on your desired surface. This is a great tool to ensure that your sticker will look exactly how you want it to when it’s applied. You can also request a proof before ordering to make sure everything is perfect.

When it comes to placing your sticker, there are several things to consider. Firstly, you want to make sure that the surface is clean and free of any dust or debris. This will ensure that your sticker has the best outcome once applied. Stickylife offers some cleaning products to help with this process.

The application process is very straightforward. Simply peel off the backing of the sticker and apply it onto the desired surface. Make sure to smooth out any air bubbles or wrinkles as you go. Stickylife offers some tools that can help with this step.

Once your sticker is applied, it is important to note that it is weathering resistant. This means it can withstand outdoor conditions without fading or peeling. Stickylife uses high-quality, solvent-based inks that are specifically designed for outdoor use.

Customers have the option to choose from a variety of sizes, shapes, and editions. Whether you want a small decal for your car window or a large sticker for a storefront, Stickylife has you covered. The shipping is also fast and reliable, so you won’t have to wait too long to receive your custom sticker.

In conclusion, if you want to create a custom sticker, Stickylife is the best place to do it. With a wide variety of options and high-quality products, you can make your sticker unique and personal. Don’t wait any longer, start designing your custom sticker today!

Custom Vinyl Decal Information

When it comes to designing high-quality custom vinyl decals, there are many features to consider. These decals are made from a vinyl material that is then printed onto and cut into the desired shape. They can be used both indoors and outdoors and have a quick turnaround time, which can help when ordering personalized stickers.

There is much more to custom vinyl decals than just sticking them onto a surface. When designing these decals, it is important to consider factors such as the type of adhesive used, the size and shape of the decals, and the specific needs and expectations of customers.

One key consideration is the type of adhesive used. There are various adhesive options available, including solvent-based adhesives that offer better durability and weather resistance. Depending on the specific application, you may need to choose a specific adhesive that will adhere well to the surface you want to place the decals on.

The size and shape of the decals also play a role in the design process. Custom vinyl decals can be made in a variety of sizes, so it is important to carefully consider the dimensions that will best suit your needs. Additionally, the shape of the decals can be customized to fit the space available and the design aesthetic you are aiming for.

When it comes to colors, custom vinyl decals offer a wide range of options. You can choose from a variety of vibrant colors to create eye-catching designs. Whether you want simple lettering or a more complex design, there are plenty of options to choose from.

Before production, it is important to clean the surface where you will be placing the decal. A clean surface will ensure proper adhesion and a long-lasting result. Additionally, it is a good idea to use a squeegee or a similar tool to apply the decal for a smooth and bubble-free application.

While the design process is important, other factors such as pre-production and shipping also play a role in the overall experience. It is important to find a reputable custom vinyl decal maker that offers a user-friendly ordering process, competitive pricing, and fast shipping.

Overall, custom vinyl decals are a great way to add a personalized touch to any space. Whether you want to create window lettering for your storefront or decorate your car, these decals offer a simple and effective way to make a statement. With the right design software and a bit of creativity, you can create vinyl decals that exceed your customers’ expectations and turn heads wherever they are placed.

Vinyl Decal Application

When it comes to applying vinyl decals, there are a few key factors to keep in mind for the best outcome. Here are some guidelines to follow:

Clean the surface: Before applying your vinyl decal, make sure the surface is clean and free of any dirt or debris. This will ensure that the adhesive sticks properly and the decal stays in place.

Size and placement: Consider the size and placement of your vinyl decal. Think about where you want it to go and what size would work best for the specific application. Some common places to put vinyl decals are windows, laptops, and cars.

Choose the right vinyl: There are a variety of vinyl options available, each with its own specific features and uses. Make sure to choose a vinyl that is suitable for the conditions it will be exposed to. Solvent-based vinyl is generally used for outdoor applications, while indoor vinyl can be used for a variety of surfaces.

Design considerations: When creating your vinyl decal, consider the colors, fonts, and overall design. Keep in mind that some fonts and designs may not translate well when cut into vinyl. It’s always a good idea to proof your design before placing an order.

Order details: When shopping for vinyl decals, make sure to provide all the necessary details for your order. This includes the specific size, quantity, and any additional options or customizations you may want.

Turnaround time: Keep in mind that the time it takes to make and ship your vinyl decals may vary. Check the website or contact the seller to get an idea of the expected turnaround time.

Application tips: When it’s time to apply your vinyl decal, use a simple tool like a credit card or squeegee to smooth out any air bubbles and ensure proper adhesion. Apply from one side to the other, and avoid stretching or distorting the decal.

Weathering: Vinyl decals are generally designed to withstand weathering and outdoor conditions. However, it’s important to keep in mind that extreme conditions like direct sunlight and harsh weather can eventually fade or damage the decal. Indoor decals, on the other hand, will typically last longer.

Collection and storage: If you’re a designer or vinyl enthusiast, you may have a collection of vinyl decals. When storing them, keep them in a clean and dry place. Avoid stacking them on top of each other to prevent sticking or damage.

These tips and guidelines should help you apply and enjoy your vinyl decals to their fullest potential. Whether you’re looking to create a personalized decal for your car or add some creative flair to your laptop, vinyl decals offer a huge variety of options to meet your specific expectations.

For more information and to shop for vinyl decals, check out sources like stickylife.com. They offer a wide selection of decals, as well as customization options and fast shipping.

Decal Shape Options

When it comes to designing vinyl stickers, you have a lot of options to choose from when it comes to the shape of your decals. Here are some of the different decal shape options available to you.

1. Default Shape: If you don’t specify a specific shape for your sticker, it will default to a simple rectangular shape. This is a common and versatile option that works well for many designs.

2. Custom Shape: If you want something more unique, you can choose a custom shape for your stickers. This allows you to create decals in the shape of your logo, a specific object, or anything else you can imagine. Just keep in mind that custom-shaped stickers may have higher minimum order quantities and longer turnaround times.

3. Die Cut Shape: Die cut stickers are cut precisely along the edges of the design, giving them a clean and professional look. This is a great option if you want your sticker to stand out and have sharp details. Die cut stickers can be made in any shape, from simple circles to intricate designs.

4. Square or Rectangle Shape: If you prefer a more traditional shape, you can choose to have your stickers cut into squares or rectangles. This is a popular option for displaying logos, lettering, or other specific details.

5. Oval Shape: Oval-shaped stickers are a classic choice that can be used for a variety of purposes. They are great for placing on windows, products, or personal items. Oval stickers can be a simple way to add a touch of style and customization to any surface.

6. Circle Shape: Circle stickers are another versatile option that can be used for a wide range of applications. They are especially popular for displaying logos, monograms, or artwork with rounded contours. Circle stickers are easy to place and can be a fun way to showcase your designs.

It’s worth noting that different shapes may offer different quantities, pricing, and turnaround times. Additionally, not all shapes may be suitable for all designs or printing processes. Before placing an order, it’s always a good idea to consult with the sticker maker or designer to ensure you select the right shape for your needs.

In addition to the shape, you can also choose from several other features when designing vinyl stickers. You can select from a variety of high-quality colors, fonts, and finishes to make your stickers truly unique. Consider the specific surfaces your stickers will be applied to, as well as the weathering conditions they may be exposed to. Some stickers are designed for indoor/outdoor use and are resistant to weathering, while others may be better suited for indoor use only.

No matter what shape or design you choose, it’s important to apply your stickers properly. Clean the surface before applying the sticker to ensure optimal adhesion. Test a small area first to make sure the adhesive sticks well. Once you’re ready to place the sticker, carefully peel off the backing and apply it to the desired surface. Press down firmly to ensure it sticks well.

In conclusion, there are many shape options available when designing vinyl stickers. Whether you want a simple rectangular shape or a custom die cut design, you can create stickers that showcase your unique style and brand. Take into consideration factors like the intended use, quantity, and printing process to ensure you get the best results. Happy sticker designing!

Other Decal Products

When it comes to decal products, StickyLife offers a variety of options to choose from. Whether you want to create custom decals for your car, laptop, or any other smooth surface, StickyLife has got you covered.

In addition to vinyl stickers, you can also choose from other decal products such as window decals, die-cut decals, and static cling decals. Each of these products can be customized to your specific needs and preferences.

StickyLife’s high-quality decal products are made from solvent-based vinyl, which ensures durability and weathering resistance. This means that your decals will remain intact and vibrant, even when exposed to harsh weather conditions.

When placing an order, you can select the size, quantity, and shape of your decals. From there, you can upload your own graphics or choose from a wide collection of pre-made designs. StickyLife’s easy-to-use online design tool allows you to add text, choose fonts and colors, and make any necessary adjustments to create the perfect decal.

StickyLife also offers helpful information and pricing details for each of their decal products. If you’re unsure about which decal option is best for you, their website provides detailed descriptions and images to help you make the right choice.

Once you’ve created your decal, you can simply add it to your cart and proceed with the ordering process. StickyLife offers fast shipping options and ships worldwide, so you can get your decals in no time.

Whether you’re looking for a fun way to personalize your belongings or a professional way to promote your business, StickyLife’s decal products are a great choice. With their high-quality materials, variety of options, and easy ordering process, you can’t go wrong.

Custom Vinyl Decal Colors

When it comes to designing vinyl stickers, the color choices are endless. With solvent-based inks and a wide range of colors available, you have the freedom to create custom decals that stand out from the crowd.

The pricing for custom vinyl decal colors may vary depending on the specific colors and quantity of decals you order. At StickyLife, we offer a simple online designer tool that allows you to select the colors and design your decals before placing your order.

Before you dive into the design process, it’s important to keep in mind a few things. First, consider the space where the decal will be applied. If it will be placed on a window, for example, you may want to choose colors that will stand out without being obtrusive. Also, consider the background color of the surface where the decal will be placed, as this can affect the visibility and readability of the lettering and graphics.

Another factor to consider is how long you want the decal to last. Vinyl decals are generally weather-resistant and can withstand outdoor conditions for several years. However, if you are placing decals in an area with high sun exposure or harsh weather conditions, you may want to select colors that are less likely to fade or show signs of weathering over time.

When designing your custom vinyl decals, it’s important to provide all the necessary information to the designer. This includes color preferences, size specifications, and any other details that are important to you. Custom vinyl decals can be used for a variety of purposes, from personalizing your vehicle to promoting your business, so be sure to communicate your expectations clearly.

Before production, a pre-production proof will be created to ensure that your decals are printed to your satisfaction. This allows you to make any necessary adjustments or changes before the final decals are printed and shipped. The production time for custom vinyl decals depends on the quantity and complexity of your order, but you can expect them to be shipped within a specific turnaround time.

When it comes to placing your custom vinyl decals, the process is simple. Remove the backing liner and place the decal on the desired surface. Use a squeegee or credit card to smooth out any air bubbles and ensure a secure application. Vinyl decals can be applied to a variety of surfaces, including windows, walls, vehicles, and more.

In conclusion, when designing custom vinyl decals, the color options are almost limitless. Take advantage of the wide range of colors available and create decals that are unique to your style and needs. With proper color selection and placement, your personalized decals will stand out and make a statement for years to come.

Parts of Personalized Decals

When it comes to creating personalized decals, there are several key parts involved in the process. Understanding these parts will help you design your own custom vinyl stickers with ease.

Design Software: To start, you’ll need design software that allows you to create and manipulate graphics and text. There are many options available, so choose one that suits your needs and skill level.

Graphics and Lettering: Once you have your software, you can choose the graphics and lettering that you want to include in your decal. Play around with different fonts, colors, and shapes to create a design that suits your style.

Proof and Order: After you have finalized your design, it’s time to proof and order your personalized decals. Make sure to review all the details and double-check for any errors before placing your order.

Quantity and Size: Decals come in different sizes and quantities, so choose the ones that best fit your needs. If you’re unsure, it’s always better to start with a smaller order and test them out before ordering a huge quantity.

Adhesive and Liner: Personalized decals generally come with an adhesive backing and a liner. The liner is the paper or film that covers the adhesive and needs to be removed before sticking the decal onto a surface.

Printing Process: Once your order is placed, the printing process begins. Depending on the printer used, the printing may be done in-house or outsourced to a professional printing company.

Pre-Production and Production: Before printing, there is a pre-production process where the design is prepared for printing. After that, the decals are printed and ready to be shipped.

Weathering and Solvent-Based: Personalized decals are made to withstand weathering and use solvent-based inks. This ensures that your decals will stay vibrant and intact, even when exposed to harsh weather conditions.

Placing and Cleaning: When you’re ready to apply the decal, make sure to choose a clean surface. Carefully remove the liner and place the decal in the desired location. Smooth out any air bubbles and wipe away any excess adhesive.

Proof and Test: After applying the decal, give it some time to cure and adhere properly. You might also want to test the decal by cleaning the surface or exposing it to different weather conditions.

Custom and Limited Edition: If you want to take your personalized decals to the next level, you can create custom or limited edition designs. These unique decals are perfect for special events or promotions.

Shopping Cart and Ordering Process: Once you’ve chosen your decals and are ready to place your order, add them to your shopping cart and go through the ordering process. Make sure to provide all the necessary details and choose the right quantities and sizes.

So, whether you’re a professional designer or just someone looking to add some personalized flair to your belongings, understanding the different parts of personalized decals will help you create better designs and ensure that your decals are made exactly the way you want them.

Decal Application Surface

When it comes to designing vinyl stickers, the application surface plays a crucial role in the overall outcome. Selecting the right surface is essential to ensure a long-lasting and high-quality result. Here are some key factors to consider:

– Smooth and Shaped Surfaces: Vinyl stickers can be applied to a variety of surfaces, but it is generally best to choose a smooth and flat surface. This will help the adhesive to stick properly and create a clean and professional look.

– Windows and Glass: Vinyl stickers are often used on windows and glass surfaces to create eye-catching graphics and lettering. Make sure to clean the surface before placing the decal to remove any dirt or dust that might prevent it from adhering properly.

– Surfaces with Liner: Some vinyl stickers come with a liner, which is a backing that protects the adhesive until the sticker is ready to be applied. When using these stickers, make sure to remove the liner before applying the decal.

– Weathering and Test Aways: Before using vinyl stickers on outdoor surfaces, it is important to test the adhesive’s ability to withstand weathering. This will help ensure that the decals will not peel or fade prematurely.

– Quantities and Surfaces: The quantity and type of surface you choose may impact the production time and cost. Some surfaces may require additional preparation or special materials, so it is important to communicate your specific requirements with the sticker maker.

– Keep it Simple: When it comes to vinyl stickers, simplicity can lead to a better outcome. Creating clean and minimalistic designs can help ensure that the message or graphics are clear and easy to understand.

– High-Quality Print: To create the best vinyl stickers, it is important to use high-quality printing technology and materials. This will help achieve vibrant colors and sharp details, ensuring that your decals stand out.

– Creative Fonts and Graphics: Fonts and graphics play a significant role in the overall design of vinyl stickers. Choose fonts and graphics that match the style and message you want to convey, while also considering readability.

– Expectations and Turnaround Time: Before ordering vinyl stickers, it is important to communicate your expectations and turnaround time with the sticker maker. This will help ensure that your order is completed within the desired timeframe.

Overall, selecting the right decal application surface is crucial for the success of your vinyl stickers. By considering factors such as surface smoothness, weathering capabilities, quantities, and design elements, you can create a collection of decals that will exceed your customers’ expectations and stand the test of time.

Decal Adhesive Details

When it comes to designing vinyl stickers, one of the most important details to consider is the adhesive that will be used. The right adhesive can make all the difference in the outcome of your sticker application. In this section, we will explore the best adhesive options for vinyl decals and provide you with all the information you need to make the right choice for your specific needs.

There are two main types of adhesive commonly used for vinyl stickers: solvent-based adhesive and water-based adhesive. Solvent-based adhesives offer a very strong bond and are ideal for outdoor use. They are resistant to moisture, heat, and UV rays, making them a great choice for car decals, window stickers, and other outdoor applications. On the other hand, water-based adhesives are more environmentally friendly and are generally used for indoor applications like wall decals or laptop stickers.

When shopping for vinyl stickers, it’s important to pay attention to the adhesive details provided by the manufacturer. Some stickers may come with a permanent adhesive that will stay in place for a long time, while others may have a removable adhesive that can be easily peeled off without leaving any residue. The minimum order quantity for stickers may also vary depending on the adhesive type and production process.

Before placing your order, it’s essential to learn about the application process for the specific adhesive used. Some adhesives may require you to clean and dry the surface before applying the sticker, while others can be applied directly onto the desired surface. It’s important to follow the instructions provided by the manufacturer to ensure a smooth and successful application.

Vinyl stickers can be cut into different shapes and sizes using a vinyl cutter or design software. The outcome of your design will depend on the shape and size of the sticker, so it’s crucial to select the right dimensions before placing your order. Keep in mind that some shapes or intricate designs may have limitations due to the cutting tool or software used.

When it comes to colors, vinyl stickers offer a wide range of options. You can choose from solid colors, gradients, or even full-color graphics to create a unique and eye-catching sticker. Just keep in mind that the colors may vary slightly from what you see on your computer screen due to differences in monitor calibration and the printing process.

After you’ve designed your sticker and selected the adhesive and shape, you can expect the production time to vary depending on the manufacturer. Some companies offer expedited shipping options if you need your stickers in a hurry, while others may require a longer processing time. It’s important to check the shipping details before placing your order to ensure that it will arrive when you need it.

Overall, the adhesive details of your vinyl sticker are crucial to its longevity and performance. Whether you’re creating a car decal, window sticker, or any other type of vinyl sticker, make sure to choose a high-quality adhesive that will stay in place without damaging the surface. By keeping these decal adhesive details in mind, you can create beautiful and long-lasting vinyl stickers that will exceed your customers’ expectations.

Decals without Minimum Quantity Limits

When it comes to placing vinyl sticker orders, many customers find themselves limited by minimum quantity requirements. However, at , we offer decals without any minimum quantity limits. Whether you need just one decal or a hundred, we’re here to fulfill your order.

With our decal printing process, we make it very simple for our customers to order the exact quantity they need. Whether you want one decal for personal use or several for a larger project, you can easily add the desired quantity to your cart without any hassle.

We apply the same high-quality standards to every decal we create, regardless of the order size. Our decals are ready to stick to any clean surface, whether it’s a car window, laptop, or any other smooth surface. The application process is quick and easy, and our decals have a long-lasting adhesive that will keep them in place for years.

When it comes to the design of your decals, the possibilities are endless. You can choose from our extensive collection of ready-made designs, or you can create a custom design using our simple online designer tool. We offer a wide range of fonts, colors, and sizes to choose from, so you can create a decal that meets your specific needs.

Before we begin the production process, we always provide a pre-production proof for your approval. This ensures that the outcome of your decals is exactly what you have in mind. If any changes need to be made, we’ll work with you to make sure everything looks great before moving forward.

Our decals are perfect for both indoor and outdoor use, as they are weathering resistant and can withstand various weather conditions. Whether you’re looking for a decal to personalize your vehicle or to promote your business, our decals are a great choice.

At Stickylife, we offer competitive pricing for every order, regardless of the quantity. We believe that everyone should be able to enjoy high-quality vinyl decals without breaking the bank. Our pricing depends on the size, quantity, and specific requirements of your order.

So whether you’re a professional designer or a creative individual, Stickylife is the best place to get vinyl decals without minimum quantity limits. Explore our website today to see our wide range of products and start designing your own custom decals.

Vinyl Decal Pricing

When it comes to pricing vinyl decals, there are a few factors to keep in mind. The cost of a vinyl decal is influenced by the size, quantity, and specific options you select. It also depends on whether you’re ordering a custom decal or selecting from a variety of pre-designed options. Here at StickyLife, we offer a wide range of high-quality custom vinyl decals to fit your specific needs.

The pricing for vinyl decals generally starts at a minimum quantity. The more decals you order, the lower the cost per decal will be. This is because the production process generally becomes more efficient as order quantities increase. If you’re not sure how many decals you might need, our online cart system will automatically calculate the cost for you based on the quantity you select.

The size of the decal is another factor that can affect pricing. Larger decals may require more vinyl material and may take longer to produce. However, larger decals can also make a bigger impact and allow for more creative design options.

In addition to size and quantity, the specific options you choose can also impact the cost. For example, if you want your decal to be a specific shape or have a special edition design, there may be additional costs associated with the customization process. However, we strive to offer a wide variety of options to fit any budget.

Another factor to consider is the application surface. Vinyl decals can be applied to a variety of surfaces, including windows, walls, and other clean, smooth surfaces. If you’re unsure whether a decal will stick to a specific surface, our team is here to help you select the right type of vinyl for your needs.

It’s important to note that our vinyl decals are made with high-quality materials that are weathering-resistant, which means they can withstand indoor/outdoor conditions without fading or peeling. This ensures that your decals will last for a long time and maintain their vibrant colors.

Whether you’re looking to create personalized decals for your car, business, or home, our vinyl decal pricing tool and online studio make it easy to design the perfect decal. Explore our variety of sizes, shapes, and graphics options to bring your creative ideas to life. With our quick turnaround time and ready-to-apply decal liner, you’ll have your decals in no time. Start designing your vinyl decals today!

Want to learn more about the vinyl decal design and printing process? Check out our blog at StickyLife for more helpful tips and insider info on how to make the most of your custom vinyl decals.

Vinyl Decal Weathering Conditions

Vinyl decals are a popular way to decorate various surfaces, from cars to windows. However, it’s important to consider the weathering conditions the decals will be subjected to before designing and placing your order. Weathering conditions can significantly impact the durability and lifespan of your vinyl decals.

When it comes to vinyl decal weathering, several factors need to be taken into account. The quantity of decals you order, the size of the decals, and the level of exposure to weather are all critical considerations.

Whether you’re designing decals for personal use or for commercial purposes, the weathering conditions should be a key consideration throughout the design and production process. Vinyl decals can withstand various weather conditions, and the right weatherproofing measures can make a significant difference.

One key factor to consider is the adhesive used in vinyl decal production. High-quality decals are typically made with solvent-based adhesives, which offer excellent weather resistance. Solvent-based adhesives are designed to withstand harsh weather conditions and can adhere well to different surfaces.

Another factor to consider is the type of vinyl used in making the decals. Some vinyl materials perform better in outdoor conditions than others. For example, cast vinyl is more durable and typically used for decals intended to last for several years or more. Calendered vinyl, on the other hand, is better suited for shorter-term applications and is not as resistant to weathering.

Additionally, the graphics and colors used in the decal design can affect weather resistance. High-quality printing processes, such as UV printing, can create vibrant and long-lasting colors that resist fading and discoloration when exposed to sunlight and other weather elements.

Before placing your order for vinyl decals, it’s essential to communicate your expectations with the decal maker. Make sure they understand the weathering conditions the decals will experience so that they can recommend the right materials and processes.

Furthermore, it’s crucial to properly apply the decal to the surface. The surface should be clean, dry, and free from any dirt or debris that could affect adhesion. Additionally, following the manufacturer’s instructions for application and allowing the decal sufficient time to adhere before subjecting it to weather elements will help ensure its longevity.

Overall, considering weathering conditions when designing and ordering vinyl decals is essential for creating high-quality, long-lasting products. By using the right materials, graphics, and application methods, you can ensure your decals withstand the test of time and weather.

At StickyLife, we understand the importance of weatherproofing vinyl decals. Our collection of decals includes weatherproof options that are designed to withstand various weathering conditions. We offer a simple and user-friendly online design tool to help you create personalized decals that meet your expectations and weathering requirements. With fast turnaround times and competitive pricing, we can deliver high-quality, custom decals right to your door. So, don’t wait! Place your order today and turn your design ideas into reality!

Turnaround Time for vinyl decals

When it comes to printing vinyl decals, the turnaround time can depend on a variety of factors. At Stickylife, we strive to provide the best and most efficient service to our customers, so you can expect a quick turnaround time without compromising on quality.

Before your vinyl decal is printed, there are a few steps that need to be taken. First, the design is created using software like Adobe Illustrator or CorelDRAW. This is where you can get creative and choose the colors, graphics, and lettering that best suit your needs. Once the design is complete, it is then sent to our printing studio.

In the printing studio, the design is used to create a high-quality vinyl decal. Our vinyl decals are made with a solvent-based adhesive that can withstand weathering for years. The decals are printed on a vinyl liner, which helps to keep the adhesive protected until they are applied to a surface.

After printing, the decals go through a pre-production process to ensure that they meet our customers’ expectations. This includes quality checks and test runs to make sure the colors, sizes, and adhesive levels are all as they should be. Once the decals pass this pre-production stage, they are then ready to be shipped.

When it comes to shipping, the time it takes for your decals to arrive depends on a few factors. The shipping method you choose and your location will play a role in the overall turnaround time. At Stickylife, we offer a variety of shipping options to choose from, so you can select the one that best suits your needs.

It’s also worth noting that there is no minimum quantity for ordering vinyl decals at Stickylife. Whether you need just one decal or a large number, we can accommodate your order. However, keep in mind that larger quantities may take longer to produce and ship.

In conclusion, the turnaround time for vinyl decals depends on a few factors such as the design process, pre-production checks, and shipping options. At Stickylife, we strive to provide our customers with a great experience from start to finish, so you can expect a quick turnaround time without sacrificing quality. Place your custom vinyl decal order with Stickylife today and experience the satisfaction of high-quality products and fast shipping!

Decal Ordering Expectations

When ordering vinyl stickers, it’s important to have certain expectations in mind to ensure a smooth and satisfying process. Here are some things to keep in mind:

- Printing Limits: Depending on the specific software or equipment used by the printing studio, there may be limitations on the size or colors that can be used. Be sure to check the information provided by the sticker maker before placing your order.

- Turnaround Time: The time it takes to create and ship your personalized decals will vary. It depends on factors such as the size of the order and the current workload of the studio. Be prepared to be patient and allow for some time before receiving your stickers.

- Minimum Quantities: Some sticker makers might have a minimum quantity requirement for orders. This is to ensure that the printing process is efficient and cost-effective. Make sure to check if there is a minimum quantity requirement before placing your order.

- Indoor/Outdoor Use: Vinyl stickers can be used both indoors and outdoors, but the durability and weathering resistance may vary. If you plan to use your stickers in outdoor environments, make sure to choose a vinyl material that is specifically designed for that purpose.

- Adhesive Quality: The adhesive used on vinyl stickers can vary in strength and effectiveness. Some stickers may have a stronger adhesive for better sticking power while others may have a more temporary adhesive that allows for easy removal. Consider your specific needs when selecting the adhesive type.

- Application Surface: Vinyl stickers can be applied to a variety of surfaces, but it’s important to ensure that the surface is clean and free of dust or debris. This will help the sticker adhere better and last longer.

- Graphics and Features: If you want to create custom vinyl stickers with specific graphics or features, make sure to communicate your requirements clearly to the sticker maker. They will be able to guide you on what is possible and offer suggestions to make your stickers look great.

- Proof and Approval: Before the stickers are printed, you may have the option to receive a proof for approval. This allows you to review the design and make any necessary changes before the stickers go into production. Take advantage of this step to ensure your stickers turn out exactly the way you want them.

- Shipping: The shipping process will depend on the location of the sticker maker and your own location. Take into account the shipping time when planning for your sticker needs.

Keeping these expectations in mind when ordering vinyl stickers will help you have a better understanding of the process and ensure that you are satisfied with the final result. Whether you are decorating your personal space or creating stickers for a specific project, vinyl decals offer a great way to add a personalized touch to any surface.

Printing the vinyl sticker

Once you have finalized your design and are ready to bring it to life, you will need to have your vinyl sticker printed. There are several options for printing vinyl stickers, and the choice you make depends on your specific needs and preferences.

One option is to order your vinyl stickers online from a printing studio or a custom sticker shop. They typically have a wide variety of options for shapes, sizes, colors, and finishes, allowing you to choose the one that best fits your creative vision. Most of these shops also offer high-quality printing and quick shipping, making it a great choice if you need your stickers in a hurry.

If you’re a designer or a creative individual, you may prefer printing the vinyl stickers yourself. In that case, you will need a vinyl sticker printer and the necessary materials. You can find vinyl sticker printers suitable for both home and professional use. It’s important to choose a printer that allows you to print high-quality decals and provides specific features like solvent-based ink and a liner for easy application.

Before printing, make sure your design is set up correctly. Use a design tool like Adobe Illustrator or CorelDRAW to create vector graphics, which can be resized without losing image quality. Convert any text to outlines to avoid potential font issues, and be aware of any bleed or margins requirements set by the printing studio. Finally, save your design in a file format recommended by the printing studio, commonly PDF or EPS.

When it comes to printing vinyl stickers, the process is generally straightforward. Load the vinyl material into the printer, making sure it’s clean and free from any dust or debris. Choose the appropriate settings on your printer, such as the print quality and the color mode. Then, hit the print button and watch as your design comes to life on the vinyl material.

After printing, you can apply a clear laminate or a layer of clear coat to protect the printed design from fading or scratching. This step is optional but recommended, especially for stickers that will be exposed to outdoor conditions or heavy use.

Once your vinyl stickers are printed, you’re ready to start using them. Peel the sticker away from its backing, also known as the liner, and apply it to the desired surface. Make sure the surface is clean and smooth for best adhesion. Vinyl stickers can be applied to a variety of surfaces, including windows, cars, laptops, and more. Whether you’re using the sticker for personal or business purposes, they are a great tool for adding a touch of customization to your belongings and promoting your products or collection.

Whether you choose to order vinyl stickers or print them yourself, the outcome is a creative and unique product that represents your personal style. Have fun with the process and let your imagination run wild. After all, the possibilities are endless when it comes to designing and printing vinyl stickers.