Making soap can be a creative and rewarding hobby, allowing you to customize the ingredients and scents according to your preferences. Whether you want to make soap for personal use or as handmade gifts for your loved ones, the process of soap making is relatively simple and can be done with basic equipment. This article will provide you with a step-by-step guide on how to make homemade soap.

Before we begin, it’s important to understand the basic chemistry behind soap making. Soap is made through a chemical reaction called saponification, which occurs when a fatty acid (such as oils or fats) reacts with an alkali, usually sodium hydroxide (lye). This reaction produces soap, as well as glycerin, a natural byproduct of the process. Glycerin is a great moisturizer and adds to the overall benefits of using handmade soap.

To make soap, you will need a few essential ingredients. The main ingredients are oils or fats, which will be used to make the soap base. Common oils used in soap making include olive oil, coconut oil, and shea butter. You’ll also need lye, which is a key component in the saponification process. Please note that lye is a caustic chemical and should be handled with care. Make sure to wear protective gloves and goggles when handling lye.

Once you have gathered all the necessary ingredients and equipment (such as a heatproof container, weighing scale, and a double boiler), you can start the soap-making process. First, measure out the oils or fats and weigh them to ensure accurate proportions. Melt these oils or fats in a double boiler until they become a clear liquid. Meanwhile, dissolve the lye in water and let it cool down.

When both the oil mixture and lye solution have cooled to around the same temperature (between 100 to 120 degrees Fahrenheit), slowly pour the lye solution into the oils while stirring continuously. This step is crucial to ensure that the lye and oils are thoroughly mixed together. Be cautious and avoid any splashes or spills, as lye can be dangerous when in direct contact with the skin.

Once the lye and oil mixture is well combined, you can add other ingredients to customize your soap. Some popular additions include essential oils for scent, honey or milk for added moisture, or even natural colorants like berry juices. Mix these additional ingredients well into the soap base until everything is fully incorporated.

Next, pour the soap mixture into soap molds or a lined baking dish. You can use a variety of molds, from traditional square shapes to more unique and creative designs. Smooth the top of the soap mixture with a spatula or the back of a spoon.

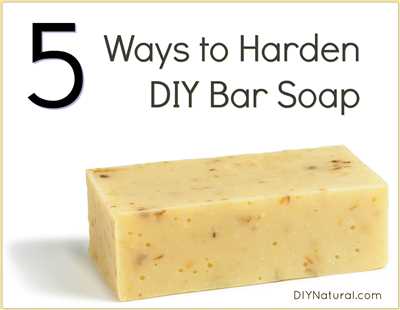

Now, you’ll need to let the soap cure and harden. The soap will go through a process called “saponification,” during which the oils and lye react and turn into soap. This usually takes about 24 to 48 hours. Once the soap has hardened, you can unmold it and cut it into bars or desired shapes.

Finally, place the soap bars in an open, well-ventilated area to fully cure. This can take anywhere from a few weeks to several months, depending on the recipe and desired hardness. During this time, the soap will continue to lose excess moisture and become milder and longer-lasting.

And there you have it, a basic overview of how to make soap at home. Although the process requires some precision and safety precautions, soap making can be a fun and fulfilling hobby. Once you’ve mastered the basics, you can experiment with different recipes and techniques to create unique and personalized soaps that suit your preferences and tastes.

- How to Make Homemade Soap

- Gather All Your Ingredients

- Melt the Soap Base

- Add Your Fragrance and Colorants

- Pour the Soap Mixture into Molds

- Let the Soap Cure

- Enjoy Your Homemade Soap

- Making Soap: A Basic Chemical Reaction

- Watch Now How to Make Your Own Soap

- Melt and Pour Soap

- Pros of MP Soap

- Cons of MP Soap

- How to Make Soap

- STEP 1

- STEP 2

- STEP 3

- STEP 4

- STEP 5

- STEP 6

- For Cold Process Soap

- For Hot Process Soap

- Ingredients and equipment

- Videos:

- Making soap with fresh ingredients🍉🥥🍋🥒🍊 A compilation

How to Make Homemade Soap

Making your own homemade soap can be a great and rewarding hobby. Not only is it a creative outlet, but it also allows you to control the ingredients that go into your soap, making it suitable for your specific needs and preferences. Whether you’re a beginner or an experienced soap maker, this step-by-step guide will walk you through the basics of making handmade soap at home.

Gather All Your Ingredients

Before you begin, make sure you have all the necessary ingredients and equipment for the soap-making process. The basic ingredients for homemade soap include a soap base (such as melt and pour soap base or cold process soap), fragrance or essential oils, colorants, and additives like almond oil or oatmeal for texture.

It is important to weigh your ingredients accurately using a kitchen scale to ensure the right proportions. For safety, you should wear gloves and protective eyewear throughout the soap-making process.

Melt the Soap Base

Start by melting your soap base. If you’re using melt and pour soap, cut it into small, even pieces and melt it in a double boiler or in the microwave. If you’re using the cold process soap method, follow a soap recipe to create your own soap base from scratch.

Be cautious when handling the melted soap base as it can be very hot. Stir it gently and continue heating until it has fully melted.

Add Your Fragrance and Colorants

Once the soap base is fully melted, it’s time to add your fragrance and colorants. Choose scents and colors that match your personal preferences. Add the fragrance oil and colorants slowly and stir them into the soap base until they are well combined.

Pour the Soap Mixture into Molds

Now that your soap mixture is fully mixed, it’s time to pour it into molds. Silicone molds are a popular choice for homemade soap making as they are easy to use and allow for easy release of the finished soap. Pour the soap mixture into the molds and tap them gently to remove any air bubbles.

Let the Soap Cure

After pouring the soap mixture into molds, let it cure for at least 24 hours or follow the specific curing time mentioned in your soap recipe. During this time, a chemical reaction called saponification occurs, which turns the mixture into solid soap.

Once the soap is cured, carefully remove it from the molds and place it on a rack or a piece of wax paper. Allow it to cure for several weeks, preferably around 4-6 weeks. This process, known as the curing stage, allows the soap to harden and improve its quality.

Enjoy Your Homemade Soap

After the curing process is complete, your homemade soap is ready to be used or gifted! Package it in an attractive way or simply enjoy using it yourself. Homemade soap makes a great personalized gift for friends and family, and the satisfaction of making your own soap is truly fulfilling.

Now that you have an overview of the soap-making process, it’s time to try making your own homemade soap. Experiment with different fragrances, colors, and additives to create unique bars that suit your preferences. Have fun and enjoy the rewarding experience of making high-quality, handmade soap from scratch!

Making Soap: A Basic Chemical Reaction

Making soap is a fascinating project that brings together the great worlds of art and science. It is a process that involves a basic chemical reaction, turning fats or oils into soap through a process called saponification. This transformation is achieved by combining fats or oils with an alkali, usually sodium hydroxide (lye), to create a soap base.

There are different ways to make soap, but one of the easiest and most popular methods for beginners is the melt-and-pour technique. This method eliminates the need for weighing ingredients and handling potentially hazardous chemicals, as it uses pre-made soap base. Melt-and-pour soaps are a great way to get started and allow for creative expression by adding colors, fragrances, or exfoliants such as oatmeal or berry seeds.

If you want to make your own soap from scratch, the cold process is a widely used method. It requires weighing and mixing fats or oils with an alkali, such as sodium hydroxide, while watching the chemical reaction take place. This process can take several hours or even days as the soap cures and hardens. The hot process is a faster alternative, as it involves cooking the soap mixture in a double boiler until it reaches the desired stage.

While making soap can be a fun and rewarding process, it’s important to take some precautions. Working with lye can be dangerous, so protective equipment such as goggles, gloves, and long sleeves should be worn. It’s also advisable to work in a well-ventilated area, away from children and pets.

One of the pros of making your own soap is that you have full control over the ingredients used. This allows for customization and the option to create soaps that cater to specific skin needs or personal preferences. However, there are also some cons to consider. The process requires time, patience, and the use of specialized equipment. Additionally, the chemistry involved may seem intimidating for beginners.

Once the soap is ready, it can be sliced into bars or molded into different shapes. It should then be left to cure for at least 4 to 6 weeks, during which time it will harden and fully saponify. The end result is a firm and long-lasting soap that provides a luxurious lather and moisturizing properties.

In conclusion, making soap is not only a practical skill, but also a creative outlet. Whether you choose the melt-and-pour or cold/hot process method, making your own soap allows you to take control of the ingredients and create a product that is tailored to your needs. So why not give it a try and enjoy the satisfaction of making something truly unique!

Image credit: Pixabay

Watch Now How to Make Your Own Soap

Soap making can be a fun and creative activity that allows you to customize your soap with different colors, scents, and ingredients. If you’ve ever wondered how to make your own soap at home, this step-by-step guide will show you how!

There are several methods to make soap, but one of the easiest and most popular is the melt-and-pour method. This basic process involves melting a pre-made soap base, adding your desired ingredients, and then pouring the mixture into molds to cool and harden.

Here’s what you’ll need to get started:

- A melt-and-pour soap base

- Colorants such as soap dyes or natural options like berry juices

- Fragrances or essential oils

- Additives like honey, almond milk, oatmeal, or other items for texture and benefits

- Molds to shape your soap

- Equipment such as a double boiler or microwave-safe bowl

- Protective gear, such as gloves and goggles

Once you have all your ingredients and equipment ready, you can start the soap-making process. Follow these steps carefully:

- Weigh out the amount of soap base you’ll need and cut it into small pieces.

- To melt the soap base, use a double boiler or microwave-safe bowl. If using a microwave, heat the soap in short bursts, stirring in between, until fully melted. Be cautious as the soap can become hot.

- Add your colorants, fragrances, and any desired additives to the melted soap base. Stir well to ensure even distribution of the ingredients.

- Pour the soap mixture into your chosen molds. You can use silicone, plastic, or even lined cardboard boxes. Consider using fun shapes for kids or a more classic design for a sophisticated homemade soap look.

- Allow the soap to cool and harden. This can take a few hours to overnight, depending on the size and thickness of the soap.

- Once the soap is firm and fully cured, remove it from the molds. If necessary, trim off any excess or uneven edges for a professional finish.

Now you have your very own handmade soap! Remember to let your soap cure for a few weeks before using, as the curing process helps the soap become milder and harder. It’s also important to note that although the melt-and-pour method is generally considered safe, caution should still be exercised when handling the hot soap base.

Soap making is a versatile hobby that allows you to experiment with different recipes and create unique soaps for yourself, family, and friends. Whether you’re looking for a gentle soap for sensitive skin or a colorful and fragrant one, making your own soap can be a rewarding and enjoyable process. So why not give it a try?

Watch the video below for a visual overview of the soap making process:

Video: How to Make Your Own Soap

If you want to learn more about soap making, there are many resources available online. From basic recipes to advanced techniques, you can find a wealth of information to help you on your soap making journey.

Get creative and have fun making your own soap!

Melt and Pour Soap

Melt and Pour (MP) soap is a popular soap making method that is perfect for beginners or those who prefer a simpler and quicker process. It involves melting a pre-made soap base and adding your own ingredients, colors, and scents to create custom bars of soap. Here is an overview of the steps involved in making Melt and Pour soap:

- Weighing: Start by weighing your ingredients, including the soap base, any additional oils or butter, fragrance or essential oils, and colors.

- Melting: Cut the soap base into small cubes or shreds and melt it using a double boiler or microwave. Be careful to not overheat the soap as it can become too hot and lose some of its beneficial properties. Stir the soap base gently until it has completely melted.

- Adding ingredients: Once the soap base has melted, you can add in any additional oils or butter, fragrance or essential oils, and colors. Mix everything together until well combined.

- Pouring: Pour the soap mixture into molds or containers of your choice. You can use silicone molds, soap molds, or even repurposed household items such as empty yogurt containers or milk cartons. Let the soap cool and harden for several hours or overnight.

- Unmolding: Once the soap has hardened, you can gently remove it from the molds. If it doesn’t release easily, you can place the molds in the freezer for a few minutes before trying again.

- Cutting and curing: You can now cut the soap into bars and let them cure for a few days to a few weeks. Curing allows the soap to harden further and any remaining moisture to evaporate, resulting in a firmer and longer-lasting bar of soap.

Melt and Pour soap has some pros and cons. The pros include the ease and convenience of the process, the ability to customize the soap with different ingredients and scents, and the short curing time compared to other soap making methods. Some cons include the limited control over the ingredients, as the soap base is pre-made, and the fact that it may not be as long-lasting as cold process soap. However, for those who are just starting out or want a fun and quick soap making project, Melt and Pour soap is a great option.

Pros of MP Soap

MP (melt and pour) soap has gained popularity for several reasons. It is a safe and easy soap-making process, which is perfect for beginners or those who want to make their own soap without dealing with the caustic chemicals involved in the cold process soap making.

Unlike the cold process soap making, MP soap doesn’t require handling ingredients such as sodium hydroxide (lye), which can be dangerous if not handled properly. This means that there is no need for a dedicated workspace or protective equipment, making it a great project for kids to work on under adult supervision.

The MP soap-making process itself is simple. You start by melting pre-made soap base, which is available in various options such as clear, white, or even color-changing. Once melted, you can add your own ingredients, such as essential oils, fragrances, or additives like oatmeal, almond milk, or berry puree, to create different textures and scents.

One great advantage of MP soap is that it cures quickly. After pouring the melted soap mixture into your desired molds, it only takes a few hours for it to harden and become ready to use. There is no need to wait for weeks or even months for it to cure, like in the cold process soap making.

The ease of handling and the speed at which MP soap can be made also means that you can experiment with different recipes without committing too much time or energy. If you don’t like how a particular soap turned out, you can simply melt it down again and pour it into a new mold to give it another try.

Another advantage of MP soap is that it is more forgiving when it comes to mistakes or miscalculations. The step-by-step process and clear guidelines make it less likely for something to go wrong. If you do make a mistake, such as adding too much colorant or fragrance, you can still salvage the soap by slicing it into smaller pieces and using it for hand-soap or decorative purposes.

Overall, MP soap offers a great way to dip your toes into the world of soap making. It provides an overview of the soap-making process, without the need for extensive equipment or knowledge of chemistry. Whether you want to make soap for personal use or as gifts for friends and family, MP soap is a fun and accessible option.

Sources:

– “How to Make Homemade Soap” by wikiHow

– “Soap Making 101” by The Spruce Crafts

– “Melt and Pour Soap Making” by Bramble Berry

Cons of MP Soap

While melt and pour (MP) soap has its advantages, it also comes with some downsides. Here are a few cons to consider when using MP soap:

| 1. Limited control over ingredients MP soap bases have already been formulated and the ingredients cannot be altered. This means that you have less flexibility to customize the soap according to your preferences or for specific skin concerns. | 2. Chemical additives Some MP soap bases may contain chemical additives to enhance their stability or lather. These additives can be drying or irritating to sensitive skin. It’s important to carefully read the ingredient list before choosing a MP soap base. |

| 3. Limited cure time Unlike handmade cold process or hot process soaps, MP soaps do not require a cure time. While this can be convenient, it also means that the soap may not reach its full potential in terms of hardness and longevity. | 4. Sweating MP soap can sometimes sweat or create beads of moisture on its surface. This can be caused by the glycerin content in the soap base. While sweating doesn’t affect the quality of the soap, it can make it feel sticky or less appealing. |

| 5. Limited creativity With MP soap, you are limited in the ways you can customize the appearance. While you can add colorants, fragrance, and some additives, the options are not as extensive as with handmade soap where you can control every aspect of the soap’s design. | 6. Less control over saponification MP soap bases have already undergone the saponification process, so there is no opportunity to witness or control the transformation of oils and lye into soap. This stage is important for understanding the chemistry of soap making and troubleshooting any issues that may arise. |

Despite these cons, melt and pour soap can still be a great option for beginners or those who prefer a simpler soap making process. It offers a quick and easy way to make homemade soap without the need for extensive equipment or handling of caustic chemicals.

How to Make Soap

Making your own soap can be a fun and creative project. Whether you’re a beginner or a seasoned soap maker, there are basic steps and ingredients you’ll need to follow. Here’s an overview of the soap-making process:

Step 1: Gather your equipment and ingredients. You’ll need a heatproof container, a double boiler or a pot with a heatproof bowl, a mixing spoon, a quart of water, a quart of milk, a pre-made soap base or glycerin, and any essential oils or additives you want to use, such as honey, almond oil, or berry color.

Step 2: Melt your soap base or glycerin. You can do this in a double boiler on low heat, or in a microwave-safe container, stirring every 30 seconds until fully melted. Be careful when handling hot soap.

Step 3: Once your soap has melted, add any essential oils or additives. Stir well to ensure they are evenly distributed.

Step 4: Pour the soap mixture into your desired soap mold or container. You can use a silicone mold, a lined loaf pan, or even an open cardboard box lined with plastic wrap.

Step 5: Let the soap cool and harden. This usually takes a few hours or overnight. If you’re in a hurry, you can place the soap in the refrigerator to speed up the process.

Step 6: Once the soap has fully hardened, remove it from the mold and slice into bars or shapes. Your handmade soap is now ready to use or give as a gift!

Remember, when working with lye or other chemicals, always follow safety guidelines and wear protective gear. Soap making is a chemical reaction called saponification, which occurs when the alkali (lye) interacts with the oils or fats in the soap. So make sure you measure your ingredients accurately and work in a well-ventilated area.

There are many different soap recipes and techniques out there, so feel free to get creative and experiment. Some people prefer the melt-and-pour method, where you melt pre-made soap base and customize it with your own colors and scents. Others enjoy the cold process method, where you mix the ingredients from scratch and watch the saponification process unfold. Whatever method you choose, have fun and enjoy the rewarding experience of making your own soap!

STEP 1

Making soap at home can be a fun and creative process. Whether you are a beginner or an experienced soap-maker, it’s important to understand the basics of soap making.

First, start by gathering all the necessary ingredients and tools. You will need a heatproof mixing bowl or a double boiler, a quart-sized glass measuring cup, a stick blender or a whisk, a soap mold, and safety equipment such as gloves and goggles.

There are different methods of soap making, but for this recipe, we will focus on the cold process method. It involves combining oils and an alkali, such as sodium hydroxide, to initiate a chemical reaction called saponification, which turns the mixture into soap.

Before you begin, make sure there is no distraction, and you are ready to commit your full attention to the process. Soap making requires precision and cautious handling of caustic materials.

Now, let’s dive into the first step of soap making, which is melting the oils. Measure the oils and transfer them to the heatproof mixing bowl or double boiler. Heat them gently until they are fully melted.

While the oils are melting, measure the sodium hydroxide and mix it with the required amount of water. Make sure to follow safety precautions and handle the caustic material with care. Allow the mixture to cool down.

Once the oils are melted and the sodium hydroxide mixture has reached a similar temperature, slowly pour the sodium hydroxide into the oils. Use a stick blender or a whisk to thoroughly mix the two together. This mixture is called the soap batter.

At this point, you can add any desired additives such as essential oils, colorants, or exfoliants like oatmeal or almond meal. Be creative and experiment with different ingredients to make your own unique soap recipes.

Once the soap batter is well-mixed, pour it into the soap molds. Tap the molds gently on a flat surface to remove any air bubbles. If desired, you can also decorate the top of the soap with dried flowers, herbs, or soap curls.

Now, cover the soap molds with a piece of plastic wrap or a towel to insulate them. This helps the soap to go through the process called “gel phase,” where it heats up and cures itself. Leave the molds covered for 24 to 48 hours.

After the initial curing period, unmold the soap and slice it into bars. The soap may still be somewhat soft, so be gentle during this process. Place the sliced soap on a rack or a tray in a cool, dry place to cure for 4 to 6 weeks. During this time, the soap will harden and cure away excess moisture.

Voila! You have now completed the first step of making homemade soap. The soap will continue to cure and improve over time, so be patient and enjoy your handmade creation. In the next step, we will explore the curing process further and dive into the more advanced techniques of soap making.

STEP 2

Once you have gathered all the ingredients and covered your workspace, it’s time to start the soap-making process. This stage is called saponification, which is the chemical reaction that occurs when fats and oils are combined with an alkali. Sodium hydroxide, also known as lye, is the alkali used in the soap-making process.

1. Weigh out the necessary amount of lye. This is a critical step, as too much or too little lye can affect the final product. Be sure to wear gloves and work in a well-ventilated area when handling caustic chemicals like lye.

2. Weigh out the fats or oils you will be using. Different oils have different properties, so choose the ones that will give you the desired characteristics for your soap. Some common oils used in soap making include olive oil, coconut oil, and almond oil.

3. Heat the fats or oils and the lye together. You can do this either on the stove or in a microwave. If you choose to use the stove, be sure to use a double boiler or a heat-safe bowl placed over a pot of hot water to prevent the mixture from getting too hot. If you use a microwave, heat the ingredients in short bursts, stirring in between each burst.

4. Once the fats or oils and lye have melted together and reached the correct temperature, it’s time to combine them. Slowly pour the lye mixture into the fats or oils, stirring constantly. Be careful, as the mixture may be very hot.

5. Stir the mixture together until it reaches trace. Trace is the stage in soap making where the mixture has thickened enough so that when you lift your stirring utensil out of the mixture, it leaves a trail or “trace” on the surface of the soap. You can test for trace by lifting your stirring utensil out of the mixture and watching how the soap batter falls back into the pot. If it falls back into the pot in globs or ribbons, you have reached trace.

6. Pour the soap mixture into molds. Silicone molds are a popular choice for soap making, as they are easy to use and clean. Make sure to tap the molds on the counter a few times to release any air bubbles that may have formed. You can also add any essential oils or colorants to the soap at this stage if desired.

7. Now it’s time to let the soap cure. Leave the soap in the molds for 24-48 hours, or until it has hardened enough to be removed from the molds. After removing the soap from the molds, it should cure for an additional 4-6 weeks. This curing process allows the soap to fully harden and the saponification process to complete. During this time, the soap will lose moisture and become milder and harder.

That’s it! You’ve successfully completed Step 2 of making homemade soap. Stay tuned for Step 3, where we will cover the curing process in more detail.

STEP 3

Once you have gathered all your ingredients and equipment, and your lye solution has cooled to room temperature, you are ready to start making soap. This is where the chemistry of soap making, called saponification, occurs.

If you are a beginner, it is best to start with a basic soap recipe that uses a melt-and-pour soap base. This type of soap making is very easy and will give you a finished soap much faster than making it from scratch.

For those who want to make soap from scratch, the first step is to melt the oils and fats. A double boiler or a heatproof container placed in a pot of water works great for this step. As the oils melt, make sure to stir them occasionally to ensure even heating.

While the oils are melting, measure out the correct amount of sodium hydroxide, which is also called lye. It is essential to be very careful during this step as lye is caustic and can cause burns. Make sure to wear protective equipment such as gloves and goggles.

Once the oils and lye solution have reached the same temperature (around 100-110°F or 38-43°C), it’s time to mix them together. Slowly pour the lye solution into the melted oils while stirring continuously. This is a crucial step, and the mixture will start to thicken and become opaque.

At this stage, you can add any additional ingredients such as essential oils, honey, or colorants. Be creative and experiment with different recipes to make the soap your own.

After everything is well mixed, it’s time to pour the soap into molds. Make sure to line the molds with parchment paper or a plastic lining to prevent the soap from sticking. The soap may still be somewhat liquid at this point, but it will firm up as it cools.

Once the soap has been poured into the molds, cover them with a towel or a lid and let them sit undisturbed for 24 hours. During this time, the saponification reaction will continue, and the soap will start to harden and take on its final texture.

After 24 hours, the soap will have turned into a firm, but still somewhat soft, texture. At this point, you can either leave it in the molds for another 24 hours to allow it to further harden, or you can remove it from the molds and cut it into bars.

If you choose to remove the soap from the molds, place it on a cooling rack or a piece of parchment paper and let it cure for 4-6 weeks. During this curing stage, the soap will continue to harden and fully dry out. This curing time is essential for ensuring that the soap is safe to use and that any excess moisture has evaporated.

Now that you have reached the end of the soap making process, you can enjoy your homemade soap. It’s a great project to do yourself or even with kids, although be sure to supervise them closely during the lye handling stage. Soap making allows for endless creativity, and once you have mastered the basics, you can start creating your own unique soap recipes.

STEP 4

Once the soap mixture has reached the trace stage, it is time to pour it into molds. There are many ways to mold your soap, but a basic method is to use a rectangular or square mold. If you don’t have a specific soap mold, you can even use a cardboard or wooden box lined with parchment paper.

Before pouring the soap, make sure to prepare your molds by lining them with parchment paper or greasing them with a small amount of oil. This will make it easier for the soap to release from the mold once it has hardened.

If you want to add any additional ingredients, such as oatmeal, honey, or almond oil, this is the stage to do it. Simply mix them into the soap mixture and stir everything together.

Next, carefully pour the soap mixture into the molds. Try to pour the soap slowly and evenly so that it fills the molds without creating air bubbles.

Once the soap is in the molds, you have two options: you can either leave it to cure at room temperature for a few weeks, or you can place it in an open area with good airflow to help speed up the curing process.

During the curing process, the soap will harden and the remaining caustic alkali in the mixture will neutralize. Although the soap may be technically safe to use after a few days, it is recommended to let it cure for at least 4-6 weeks. This allows the soap to become milder and last longer in the shower.

While waiting for the soap to cure, it’s a good idea to weigh and slice it into bars. This will make it easier to handle and use once it’s fully cured.

Some people prefer to leave their soap in large blocks and slice off pieces as needed, while others like to individually wrap their soap bars. It’s all a matter of personal preference!

- The Basics:

- Overview – How Soap is Made

- Step 1 – Gather Your Equipment

- Step 2 – Weigh Your Ingredients

- Step 3 – Melt the Oils

- Step 4 – Mix the Lye Solution

- Step 5 – Combine the Lye Solution with the Oils

- Step 6 – Add Fragrance or Essential Oils (Optional)

- Step 7 – Pour the Soap into Molds

- Step 8 – Let the Soap Cool and Harden

- Step 9 – Remove Soap from Molds and Cut into Bars

- Step 10 – Cure and Store the Soap

STEP 5

Now that everything is prepared, it’s time to make the soap! Before you begin, make sure you have all the necessary equipment and ingredients. Safety is paramount when handling caustic chemicals, so make sure to wear gloves and work in a well-ventilated area.

1. Start by weighing out your pre-made soap base or making your own from scratch using a basic recipe. There are many creative ways to personalize your soap, such as adding color, essential oils, or even oatmeal for exfoliation.

2. Melt the soap base in a double boiler or microwave, following the instructions on the package. Be careful not to overheat it, as this can cause the soap to sweat or become too firm.

3. Once the soap base has melted, you can add any additional ingredients such as honey, almond milk, or berry extracts. Mix everything together thoroughly.

4. While the soap is still hot, pour it into your chosen molds. You can use silicone molds, plastic containers, or even lined cardboard boxes. The soap will firm up as it cools.

5. Cover the molds with a piece of clear plastic wrap and let the soap cure for at least 24 hours. During this time, a chemical process called saponification occurs, turning the mixture into soap.

6. After the curing period, you can remove the soap from the molds. If it’s still too soft, you can place it in the freezer for a short while to firm up. Be sure to let it come back to room temperature before handling.

Now you have your own handmade soap ready to use or give as gifts! Soap making can be a fun and rewarding hobby, perfect for both beginners and those with some creative chemistry skills. With a basic understanding of the soap-making process, you can experiment with different recipes and ingredients to create your own unique creations.

STEP 6

Once the soap has been poured into the mold, it’s time to let it cure. Curing is a process that allows the soap to harden and become milder and longer-lasting. This stage typically takes 4 to 6 weeks. During this time, the chemical reaction called saponification continues, and any remaining caustic ingredients such as sodium hydroxide are neutralized.

Make sure to cover the soap with a heatproof cloth or lid to prevent sweating and keep any dust or debris from settling on top. You can also wrap the soap in wax paper or a plastic wrap to help preserve moisture.

It’s important to note that handmade soap needs to be cured for a certain period of time to ensure it’s safe to use. Although the soap may be fully saponified and ready to use after this time, it’s still a good idea to allow it to cure for a few extra weeks to harden and provide a better lather.

During the curing stage, the soap will lose some of its moisture and may become smaller. This is completely normal and means that the soap is becoming denser and more concentrated. It’s also a great time to add any finishing touches, such as colorants or fragrance oils, to enhance the appearance and scent of the finished soap.

Once the soap has fully cured, it can be unmolded, cut into bars, and enjoyed! Remember to always wear gloves during this process, especially if you have sensitive skin or are working with a hot or caustic soap base.

Now that you know the basics of how to make soap, you can explore different recipes and techniques to create your own unique creations. Soap making can be a fun and rewarding hobby for beginners and a great way to involve kids in a hands-on chemistry lesson.

By making your own soap, you have complete control over the ingredients used and can customize your soap to meet your specific needs and preferences. Whether you choose to make cold process soap, melt-and-pour soap, or pre-made soap base, the options are endless.

The handmade soap community is a tight-knit group, and there are many resources and communities available for support and inspiration. So start experimenting, have fun, and enjoy the satisfaction of using your own handmade soap!

For Cold Process Soap

To make cold process soap, you will need a few key ingredients. The basic soap recipe calls for a mixture of oils, such as almond or olive oil, that will be combined with an alkali, typically sodium hydroxide (lye). This chemical reaction, called saponification, is the basis for soap making.

First, make sure to work in a well-ventilated area and wear protective gloves and eyewear. Start by weighing out your oils and melting them together in a double boiler. While the oils are melting, dissolve the lye in water or milk, stirring until it has completely dissolved.

Once the oils and lye mixture have both reached the correct temperature, usually around 100-110°F (38-43°C), you can then combine them. This step is known as “trace,” which means the mixture has thickened enough that a line or “trace” of the mixture stays on the surface before sinking back in.

At this point, you can add any additional ingredients, such as essential oils for fragrance, colorants for color, or additives like oatmeal for exfoliation. Stir everything together well and then pour the mixture into soap molds. Cover the molds with a piece of cardboard or a towel to insulate them and keep the heat in.

Now comes the waiting game. Cold process soap needs to cure and harden for several weeks before it is ready to be used. During this time, a chemical reaction called the saponification process occurs, converting the oils and lye into soap. The soap also continues to lose excess moisӒТГKale1qw4Fy8eture, making it harder and longer-lasting.

After about 24 hours, you can remove the soap from the molds and cut it into individual bars. Place the bars on a drying rack or some wax paper, and let them cure for at least four weeks. During this time, the soap will harden even more and any remaining moisture will evaporate. After the curing period, your handmade soap is finished and ready to be used!

Remember, making soap can be a fun and rewarding project, but it does require careful handling of chemicals. Always follow safety precautions and make sure to properly label your soap with the ingredients and curing date. With a bit of practice, you can create your own unique soap recipes and enjoy the great benefits of handmade soap.

For Hot Process Soap

Hot process soap making is a creative and rewarding way to make your own homemade soap. It involves a chemical reaction between oils and an alkali, usually sodium hydroxide, which is also called lye. Unlike cold process soap, hot process soap is heated during the soap-making process.

To make hot process soap, you will need basic equipment such as a heatproof double boiler, weighing scale, and soap molds. Here is a step-by-step overview of how to make hot process soap:

- Weigh and melt your oils and fats in the double boiler. Some common oils used in soap making include almond oil, coconut oil, and shea butter.

- In a separate container, weigh the sodium hydroxide (lye). Be sure to wear gloves and handle the lye with care, as it is a caustic chemical.

- Slowly add the lye to the melted oils while stirring constantly. This mixture is called the soap base.

- Cover the soap base and let it cook on low heat for about 1-2 hours. During this time, it will go through various stages, called gel phase and pudding stage, until it reaches a clear and translucent appearance.

- Once the soap base has reached the desired consistency, you can add any additional ingredients, such as fragrance or oatmeal, to the mixture. Stir well to ensure even distribution.

- Turn off the heat and let the soap cool for a few minutes. At this point, you can also add any colorants or botanicals to make your soap more visually appealing.

- Pour the hot process soap into the molds and let it sit for a few hours to firm up.

- After the soap has hardened, you can remove it from the molds and let it cure for 4-6 weeks. Curing allows the soap to harden fully and any excess moisture to evaporate, resulting in a longer-lasting bar of soap.

- Once the soap has cured, it is ready to use or give away as gifts. Hot process soap is known for its rustic and textured appearance, making it a great option for those who prefer a more natural-looking soap.

Hot process soap making may require more equipment and time compared to melt-and-pour or cold process soap, but it offers unique advantages. The hot process soap cures much faster than cold process soap, so you can start using it right away. Additionally, the heat and cooking process help to speed up the saponification reaction, resulting in a soap that is less caustic and more gentle on the skin.

Now that you know the basics of how to make hot process soap, you can get creative and experiment with different oils, scents, and additives to make your own unique soap recipes. Don’t forget to give credit to the original recipe if you share your creations!

Ingredients and equipment

When it comes to making homemade soap, there are a few key ingredients and pieces of equipment that you will need. Let’s take a look at what you’ll need for this project:

| Ingredients | Equipment |

|---|---|

| Base oils or fats | Double boiler |

| Lye, also known as caustic soda or sodium hydroxide | Weighing scale |

| Water or other liquid (such as milk) | Mixing bowls and utensils |

| Additives (such as color, scent, or exfoliants) | Thermometer |

| Essential oils or fragrance oils | Soap molds |

| Optional: honey, almond oil, or other nourishing ingredients | Canning jars or containers for curing |

The first step in making soap is to gather all your ingredients and equipment. Make sure to wear gloves and handle the caustic lye with extreme care, as it is a chemical that can cause burns. It is also important to work in a well-ventilated area and avoid contact with the lye fumes.

Next, you’ll need to melt your base oils or fats in a double boiler. This can be done on a stovetop or in a microwave, depending on the method you choose. Once melted, you can add any additional ingredients, such as honey or almond oil, to enhance the soap’s properties.

In a separate container, weigh out the appropriate amount of lye and dissolve it in water or another liquid. This mixture will become very hot, so be cautious when handling it. Once dissolved, you can slowly pour the lye solution into the melted oils while stirring continuously.

As you mix the oils and lye solution together, you’ll notice a chemical reaction called saponification occurring. This is when the oils and lye combine to create soap. The mixture will start to thicken and become more opaque as this process takes place.

Once the soap mixture reaches a trace stage, which is when it leaves a visible trail or mark on the surface, you can add any additives, such as essential oils or colorants. Be creative with your choices to make unique and personalized soaps.

When the soap mixture is fully mixed and any additions are well incorporated, you can pour it into soap molds and set it aside to cure. The curing process, which can take anywhere from 4 to 6 weeks or even more, allows the soap to firm up and finish the saponification process.

During the curing stage, the soap releases any excess moisture and cures into a hardened, long-lasting bar. It’s important to cover the molds to protect the soap while still allowing air to circulate. This can be done with plastic wrap or other suitable covers.

Once the soap has cured, it can be unmolded and cut into bars or other desired shapes. Each piece of soap is now ready to be used or gifted to others.

Whether you choose to make your soap from scratch using the cold process method or prefer the melt-and-pour technique with pre-made soap bases, soap making can be a fun and rewarding hobby. It allows you to create your own unique blends and experiment with different ingredients and scents.

If you have kids or prefer a simpler and safer alternative, you can also try making melt-and-pour soaps. This method involves melting pre-made glycerin soap base and adding your choice of color, scent, and other additives. The melted soap can then be poured into molds and cooled to create your very own handmade soaps.

As with any DIY project, it’s important to be cautious and follow safety guidelines when handling chemicals and heat. Always wear gloves, work in a well-ventilated area, and keep children and pets away from the soap-making process.