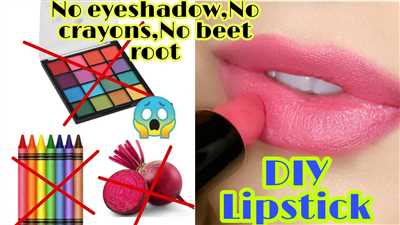

Maryam always thought that lipstick was made with a mixture of carbon-based particles, just like inorganic powder. But she was surprised to discover that many lipstick shades actually come from natural sources, including bugs. Yes, bugs! Because of their vibrant colors, bugs are considered a valuable source of pigments in the cosmetic industry. And while some people may find it a bit unsettling to think that their favorite red lipstick is made from insect juice, it’s worth understanding how these pigments are produced and how they can be used to make stunning lipstick shades.

When it comes to making lipstick, the first thing you will need is the right equipment. Lipstick production requires specialized machinery and ingredients. While it may seem like a complex process, it’s actually quite fascinating. The most important ingredient in lipstick making is a stable mixture of pigments, oils, and waxes. These ingredients are carefully selected to ensure the lipstick’s stability, color, and texture.

One of the tricks in making lipstick is to get the right balance of organic and inorganic pigments. Organic pigments are derived from natural sources, such as plants, while inorganic pigments are made from minerals or synthetic materials. The choice of pigments will determine the color and translucency of the lipstick. Additionally, other ingredients like oils and waxes are added to make the lipstick glide on smoothly and give it a glossy finish.

Production of Lipstick

When it comes to the production of lipstick, there are many factors to consider. The first and most important step is sourcing the right ingredients. Lipstick is primarily made with carbon-based sources, such as waxes, oils, and pigments. These ingredients can be obtained from various sources, including plants, animals, and minerals.

Lipstick making, while it may seem simple, requires specific equipment and techniques. The ingredients must be carefully measured and mixed to create the desired formula. Starting with a base mixture of waxes and oils, the pigments are then added to give the lipstick its color. It is important to note that not all pigments are suitable for use in cosmetics. The industry has strict guidelines and regulations regarding the safety and stability of the pigments used in lipstick production.

One of the tricks of lipstick production is achieving the right texture. Different types of waxes and oils can be used to create lipsticks with varying consistencies, such as matte or glossy. The addition of certain powders can also help to enhance the texture and finish of the lipstick.

When it comes to packaging, there are many options available. Lipsticks are usually housed in a cylindrical tube, with a twist mechanism to push the product up for application. The tube can be made from various materials, including plastic or metal. Some companies even opt for more eco-friendly packaging options, using materials like bamboo or recycled plastic.

In the production of lipstick, the color is of utmost importance. Many shades and variations are available, ranging from classic reds to translucent pinks. The pigments used in lipstick production are carefully selected and tested for their color stability and intensity.

While lipstick may seem like a simple cosmetic product, a lot of thought and effort goes into its production. From sourcing the ingredients to formulating the right mixture and packaging the finished product, each step in the lipstick production process is crucial in creating a high-quality lipstick that is loved by consumers.

So, the next time you apply your favorite shade of lipstick, take a moment to appreciate the extensive production process that goes into creating that perfect color and texture.

Understand the Industry

To truly understand the lipstick industry, it is important to know where it all begins. Lipstick is made by combining a mixture of various ingredients, including pigments, powder, and oils. The pigments provide the color, while the powder helps to give the lipstick its texture. Oils are added to provide moisture and enhance the life of the product.

One of the key ingredients in lipstick pigments is a substance called carmine. Carmine is a red pigment that is derived from the cochineal insect, making it an organic and natural source. Cosmetic companies have used carmine for years to create various shades of red lipstick.

However, not all lipstick pigments come from insects. Inorganic pigments, such as iron oxides, are also commonly used in lipstick production. These pigments are synthesized from minerals and are often used to create darker and more opaque shades.

When making lipstick, the industry always considers factors like stability and shelf life. Lipstick should remain intact and not easily break or crumble, even when applied to the lips. The right mixture of ingredients and the use of proper packaging can help achieve this.

Lipstick production requires specialized equipment and knowledge. Maryam, an expert in the industry, explains that “making lipstick is like an art, and there are always tricks and techniques to get the best results”. From choosing the right ingredients to adjusting the particle sizes, every step in the process is crucial for creating high-quality lipstick.

While there are many different types of lipstick available in the market, it is worth noting that not all of them are considered safe for use. Some lipstick brands may contain harmful ingredients or toxins, which can be harmful to your health. It is important to always check the ingredient list and choose cosmetic products from trusted sources.

So, next time you think about what goes into making your favorite lipstick shade, remember the intricate process and industry standards that go into it. Lipstick is more than just a color on your lips – it is the result of years of research, innovation, and cosmetic expertise.

Translucent Tricks

In the world of lipstick making, there are many tricks of the trade that come into play when creating a translucent shade. Translucent lipsticks are made with a mixture of inorganic pigments and organic ingredients, which give them their unique color and translucency.

When it comes to the ingredients used in lipstick production, the most common source of color comes from carbon-based bugs. Yes, you read that right – bugs! These bugs are considered a natural source of red pigment, and they are carefully sourced and processed to extract the desired color. The pigment is then mixed with other ingredients to create the right shade.

Not all lipstick shades require bug-derived pigments, though. There are many other sources of color available, both organic and inorganic. From red iron oxide to cosmetic-grade mica powder, the options are endless. The choice of pigments depends on the desired shade and the overall aesthetic of the lipstick.

Making translucent lipsticks is not as simple as mixing pigments and ingredients together. The right equipment and techniques are essential to achieve the desired result. Lipstick production involves a careful balance of heating, cooling, and mixing to ensure that the lipstick has the right texture and consistency.

Translucent lipsticks are also known for their glossy finish. This is achieved by adding gloss particles to the mixture, giving the lips a shiny and reflective look. It’s worth noting that not all lipsticks have a glossy finish – some prefer a matte or satin look instead.

When it comes to packaging, translucent lipsticks often come in sleek and elegant designs. The packaging is designed to reflect the overall aesthetic of the lipstick and to appeal to consumers. The packaging can range from simple and minimalistic to bold and eye-catching, depending on the target audience.

In conclusion, translucent lipsticks are made with a careful mixture of organic and inorganic ingredients, sourced from various natural and synthetic sources. The production process involves a combination of heating, cooling, and mixing techniques to achieve the desired color, texture, and finish. Whether you prefer a glossy or matte look, there are tricks in the lipstick industry to satisfy every individual’s taste and style.

Lipstick making equipment to get the right mixture

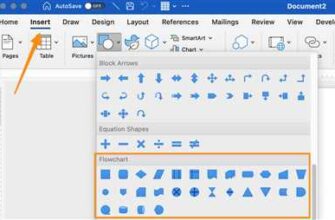

When it comes to making lipstick, it is important to have the right equipment in order to achieve the desired results. Lipstick manufacturing is a complex process that requires precision and understanding of the ingredients and their properties. Lipstick making equipment is specifically designed to ensure that the mixture of ingredients, including pigments, waxes, oils, and other additives, is properly blended to create a high-quality lipstick product.

One important piece of equipment used in lipstick production is the mixer. The mixer is responsible for thoroughly blending all the ingredients together, ensuring that they are evenly distributed and properly mixed. This is important because any variation in the mixture can result in inconsistencies in color and texture. The mixer works by using rotating blades or paddles to agitate the ingredients, allowing them to combine and form a homogenous mixture.

In addition to the mixer, there are other pieces of equipment that are necessary for making lipstick. This includes the heating system, which is used to melt the waxes and oils, providing a liquid base for the other ingredients. The heating system ensures that all the components are properly mixed and melted before the mixture is poured into molds or containers for further processing.

Another crucial piece of equipment is the lipstick mold. The lipstick mold is responsible for shaping the lipstick into its final form. These molds can vary in size and shape, depending on the desired lipstick design. Once the mixture is poured into the molds, it needs to be cooled and solidified before it can be removed and packaged.

When it comes to achieving the right color for lipstick, the industry relies on a wide range of pigments and colorants. These colorants can be obtained from both organic and inorganic sources. Organic pigments are derived from natural sources, such as plants, while inorganic pigments are made from synthetic materials. The choice of pigments depends on the desired shade and the stability requirements of the lipstick. Some pigments, such as red pigments, are more commonly used in lipstick making.

In the past, red pigments were often made from crushed insects, such as cochineal bugs. However, with the advancement of technology and the availability of alternative sources, most lipstick manufacturers now use synthetic pigments. These synthetic pigments are considered safe for use in cosmetic products and provide more stability and consistency in color.

It is worth noting that the process of making lipstick involves not only the right equipment but also various production tricks and techniques. Some manufacturers use translucent or clear packaging to enhance the color of the lipstick, while others add gloss or shimmer particles to create a more vibrant finish. The choice of equipment, ingredients, and production methods will depend on the desired outcome and the preferences of the cosmetic brand.

In conclusion, lipstick making equipment plays a crucial role in achieving the right mixture of ingredients. From mixers to molds, each piece of equipment has a specific purpose in the production process. The choice of ingredients, including pigments and additives, is also important in determining the color, texture, and stability of the final product. With the right equipment and knowledge, cosmetic manufacturers can create high-quality lipsticks that meet the demands and expectations of consumers.

Stability in organic and inorganic pigments

When it comes to making lipstick, the stability of the pigments used is always a crucial factor to consider. Lipstick is available in many shades and colors, and the pigments used in their production can be either organic or inorganic.

Organic pigments are carbon-based and come from natural sources like insects, plants, and even food. These pigments are often used in translucent or glossy lipstick products. The use of organic pigments in lipstick production is worth considering because they offer a wide range of shades and colors.

On the other hand, inorganic pigments are made from non-carbon-based sources and are primarily used for vibrant and long-lasting colors. These pigments are more stable than organic pigments, which means they have a longer shelf life and are less likely to degrade over time.

Stability is a key factor in the lipstick industry because consumers want to ensure that the color of their lipstick does not change or fade over time. Inorganic pigments tend to provide the most stability in terms of color retention, making them the preferred choice for many lipstick manufacturers.

However, making lipstick is not just about choosing the right pigments. It requires a mixture of ingredients and tricks to get the desired color, texture, and longevity. Lipstick production involves a careful selection of equipment, starting from the packaging and ending with the powder particles used to create the lipstick.

Maryam, a cosmetic industry expert, says that while organic pigments can provide beautiful shades, they often require special attention to stability. “Organic pigments can be more susceptible to degradation from environmental factors like light and heat,” she explains. “That’s why it’s important to understand the tricks of the trade and choose the right ingredients to ensure the stability of the lipstick.”

So, whether manufacturers choose organic or inorganic pigments for their lipstick products, stability is a top consideration. It is important to understand the difference between these two types of pigments and the potential challenges that come with using each. Both organic and inorganic pigments have their own advantages and limitations, and it’s up to the manufacturers to weigh the pros and cons to create the best lipstick products.

Where does the red lipstick color come from? Bugs Say what

When it comes to making lipstick, many people think of the bright and bold red shades that are often the most popular. But have you ever wondered where the red color in lipstick actually comes from? It might surprise you to learn that the answer is bugs.

Yes, bugs. Specifically, a type of insect called the cochineal insect, which is found in various parts of the world, including Mexico and South America. These insects feed on certain cacti and produce a red pigment known as carmine. The carmine pigment is harvested by drying and crushing the bugs, turning them into a fine powder.

This red insect-based pigment is then used in the production of lipstick, among other cosmetic products. While some people may find the idea of using bug-based ingredients in their makeup a bit off-putting, it’s worth considering that the use of insects in cosmetics is not uncommon, and these bug-derived pigments have been used for thousands of years.

In fact, the use of bugs in cosmetics goes back to ancient times when Egyptians would crush insects to create powders and dyes. Today, bug-derived pigments are still widely used and are considered organic and natural alternatives to synthetic dyes.

So, if you’ve ever wondered what gives red lipstick its vibrant and eye-catching color, now you know. It’s all thanks to these tiny bugs and their precious carmine pigment.

Of course, not all red lipsticks on the market contain bug-derived pigments. There are many synthetic alternatives available, and some lipsticks use inorganic pigments to achieve a similar red shade. But for those who prefer organic and natural ingredients, bug-derived pigments are a popular choice.

When it comes to making red lipstick, the mixture of ingredients and tricks used vary from brand to brand. Some cosmetics companies prefer to enhance the red color with translucent pigments, while others opt for a more opaque and glossy finish. The right mixture and packaging can make all the difference in achieving the perfect shade of red.

So, the next time you apply that perfect red lipstick, take a moment to appreciate the bugs that made it possible. Bugs may not be the first thing that comes to mind when you think of makeup, but their contribution to the world of cosmetics is undeniable.

And who knows, maybe Maryam, that little insect with a short life, will feel proud to have made such an impact in the world of beauty.

Sources

When it comes to making lipstick, there are many sources that provide the necessary ingredients and equipment. Let’s take a look at some of them:

| Insects | These little bugs are actually an important source of color for lipstick. Certain insects, like beetles, contain a red pigment called carmine, which is commonly used in cosmetics. |

| Food and cosmetic industry | The food and cosmetic industry provides a variety of ingredients that are used in lipstick production. These can include oils, waxes, and powders. |

| Equipment | Specialized equipment is needed for the production of lipstick. This includes mixers, molds, and packaging machinery. |

| Packaging | To package the finished lipstick, various types of containers and tubes are used. These can range from simple plastic tubes to more elaborate and decorative packaging. |

| Tricks of the trade | The lipstick industry has developed a number of tricks to ensure the stability and longevity of the product. These can include using specific ingredients or techniques to enhance the color and texture of the lipstick. |

Understanding where and what these sources are is crucial in the production of lipstick. Different sources provide different shades and qualities, so it’s always worth considering where the ingredients come from and what they are made of. While some pigments and ingredients may be considered inorganic or synthetic, there are also many organic options available.

In conclusion, making lipstick is a complex process that relies on a variety of sources and industry knowledge. From insects to equipment, the right ingredients and techniques are necessary to create the wide range of colors and finishes that are available in the market. So, next time you reach for that red lipstick, remember all the work and creativity that goes into making it!